Jan . 09, 2025 11:26 Back to list

wire mesh manufacturers

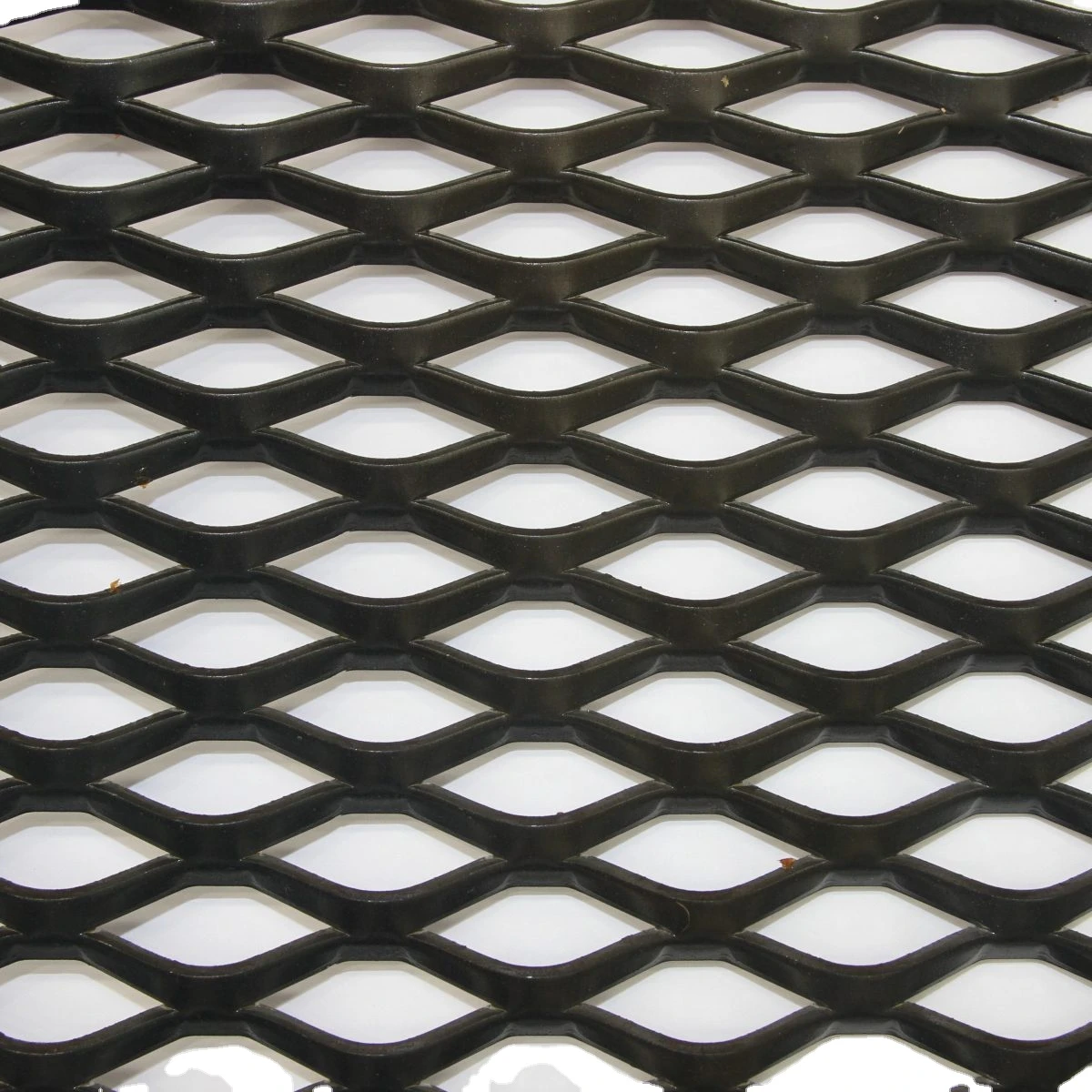

Another hallmark of a trustworthy wire mesh manufacturer is its dedication to innovation and customer satisfaction. Top manufacturers often engage in R&D initiatives, working collaboratively with clients to develop custom solutions that meet unique challenges. This not only enhances product functionality but also builds long-term partnerships based on reliability and mutual benefit. The importance of an experienced wire mesh manufacturer becomes evident when considering issues such as mesh uniformity, tensile strength, and load-bearing capacity. Inferior manufacturing can lead to inconsistencies that compromise the mesh's integrity, resulting in failures that could have severe repercussions depending on the application. Hence, selecting a manufacturer with a proven track record and positive client testimonials is imperative. Furthermore, customer support and after-sales service are critical components of a trustworthy manufacturer. Providing timely assistance and addressing any concerns effectively are signs of a manufacturer’s commitment to nurturing customer relationships. This support ensures that clients can rely on expert advice and maintenance services long after the initial purchase. In conclusion, the journey to finding an exemplary wire mesh manufacturer encompasses a detailed evaluation of several attributes such as expertise in production, authoritativeness in quality assurance, a commitment to innovation, and the cultivation of trust through excellent customer service. By choosing a manufacturer that embodies these qualities, businesses and consumers alike gain a partner capable of delivering the precision and quality needed to excel in their respective projects.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA