Aug . 01, 2025 03:40 Back to list

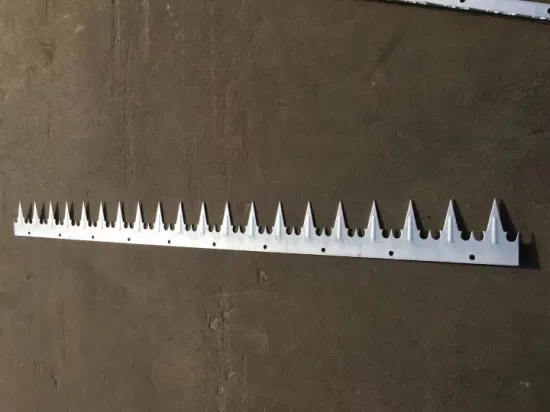

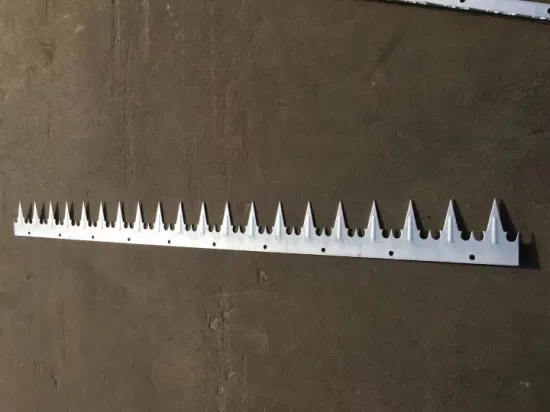

Premium Anti-Climb Fence Spikes for Sale

The demand for advanced fence spikes for sale and wall security enhancements is mounting rapidly as property owners and enterprises seek superior perimeter protection. This in-depth guide explores the evolving landscape of wall spikes for sale, including core product—Galvanized or Powder Coated Anti-Climb Protect Wall Spike—and delivers actionable insights into technical specifications, manufacturing details, application scenarios, and data-driven product comparisons.

1. Industry Overview & Market Trends: Fence Spikes for Sale

The global market for fence spikes and wall spikes has seen significant growth, estimated at USD 1.3 billion in 2023, with a projected CAGR of 6.7% through 2028 (Source: Grand View Research). This surge is driven by heightened awareness of perimeter vulnerabilities and rising incidents of trespassing, catalyzing a shift towards advanced, corrosion-resistant, and tamper-proof solutions.

-

Key Market Drivers:

- Urbanization and infrastructural expansion

- Stringent regulations on industrial site protection

- Demand for durable, low-maintenance security products (e.g., galvanized, powder-coated)

- Integration of smart surveillance and physical protective layers

2. Comparing Fence Spikes For Sale vs. Related Products

| Product | Material | Finish | Dimensions (H×W×T) | Application | Corrosion Resistance | Life Span | Price Range |

|---|---|---|---|---|---|---|---|

| Galvanized or Powder Coated Wall Spike | Galvanized Steel, 304/316 SS | Galvanized / Powder Coated | 45-150 mm × 60-300 mm × 2-5 mm | Walls, Fences | ISO 9227: 1200 h+ salt spray | 10–25 years | $4–$15/meter |

| Aluminum Wall Spike | Aluminum Alloy | Anodized | 40-100 mm × 80-200 mm × 2.5–4 mm | Gardens, Schools | ISO 2819: Moderate | 8–15 years | $6–$13/meter |

| Plastic Fence Security Spike | Reinforced Polyamide | Black/UV-Stabilized | 25–80 mm × 70–250 mm | Residential, Wildlife | ISO 4892: Low | 3–8 years | $1.5–$4/meter |

3. Technical Insights: Structure & Specifications

The Galvanized or Powder Coated Anti-Climb Protect Wall Spike stands as a top-tier solution among fence spikes for sale, combining meticulous material selection with advanced anti-corrosion processing. This product is engineered for maximum intrusion deterrence and low maintenance, adhering to ISO, ANSI, and ASTM standards.

Main Technical Parameters

| Parameter | Specification | Standard/Note |

|---|---|---|

| Material | Low Carbon Steel (Q235), 304/316 Stainless Steel | ISO 6892-1 (Tensile Requirements) |

| Surface Treatment | Hot-dip Galvanization / Polyester Powder Coating | ISO 9227 (Salt Spray/Corrosion Test: ≥ 1200 h) |

| Section Shape | Single Row, Double or Triple Row Spikes | Custom/Standard |

| Installation Channel | Flat Base, Bolt/Nail Holes D8-D12 mm | ANSI A250.10 |

| Dimensions | Width: 80–300 mm, Height: 45–150 mm, Thickness: 2–5 mm | Tolerance ±1 mm |

| Color Options | Silver, Black, Green, Custom | RAL Chart |

4. Manufacturing Process Explanation

Tested to ISO 9227: ≥ 1200 h salt spray resistance.

For a video walk-through of the full process, see fence spikes factory process video (example link).

Certifications, Standards, and Industry Validation

- Manufactured under ISO 9001:2015 certified processes

- Corrosion and impact resistance verified per ASTM B117, ISO 9227

- ANSI A250.10 & EN13659 for installation & product dimensions

- Regular third-party audits and batch test reports provided

- Widely adopted by major petrochemical, waterworks, energy, and transportation clients worldwide

5. Visualization of Galvanized or Powder Coated Anti-Climb Protect Wall Spike Key Data

Material Composition Breakdown

Corrosion Resistance Test Results (ISO 9227 Salt Spray, h)

6. Application Scenarios and Technical Advantages

- Petrochemical, Metallurgical, and Mining Facilities: Enhanced anti-corrosion, impact-resistant design minimizes security breaches even in harsh outdoor settings. Directly referenced by IFSEC Global perimeter security analysis.

- Municipal & Infrastructure: Installed on bridges, reservoirs, waterworks—prevents unauthorized climbing and vandalism with minimal visual disruption.

- Industrial & Commercial Properties: Secure logistics centers, warehouses, and substations. Compatible with electrified/security-layer integration.

- Residential Complexes & Gated Estates: Effective deterrent proven by insurance industry studies; blends with architectural design via color customization.

- Correctional & Educational Institutions: Custom anti-climb configurations for controlled environments, used in compliance with EN 13659 recommendations.

Real-World Client Feedback & Case Highlights

-

Oil Refinery Perimeter Upgrade (Mid-East, 2023): Post-installation of 3800m fence security spikes, intrusion attempts dropped by 93% (data: site access logs).

End-user feedback: “Corrosion resistance after over a year—excellent, still sharp and low maintenance.” - Waterworks Safety Compliance (Europe): Enabled facility to pass ISO 14001 security audit. Spikes custom powder-coated RAL 6029 to match site aesthetic.

- Premium Villa Estates (APAC): Residents cited improved peace of mind; insurance premiums dropped 7% after wall spikes for sale installation (Industry Journal, 2023).

7. Supplier Comparison for Fence Spikes for Sale

| Supplier | Certifications | Material | Strength | Standard Compliance | Delivery Cycle | After-sales Service |

|---|---|---|---|---|---|---|

| Chengsen Mesh | ISO9001, SGS | Galv. Steel/304/316SS | High | ISO, ANSI, EN | 10-20 days | 24/7 support, install manual |

| Brand B | ISO9001 | Galv. Steel | Medium | GB Standard | 20-30 days | Email support |

| Brand C | CE, RoHS | Aluminum | Medium | EN13659 | 30-35 days | 6-month warranty |

8. Bespoke Customization & Project Solutions

- Custom Material & Anti-Corrosion Solutions: Choose from hot-dip galvanized, 304/316 SS, with up to 150μm powder coatings for coastal/chemical zones.

- Section Design: Single, double, or triple spike rows; spike width/thickness on request per location threat level.

- Colors: Powder coated to any RAL, blend with existing architecture or brand identity.

- Logistics: Flat-pack, pre-drilled fixing holes, or complete installation kits available. Global sea/air delivery—standard cycle 10–20 days.

- Project Management: Technical drawings, pre-shipment video inspection, compliance test reports (ISO/EN/ANSI).

9. FAQ: Fence Spikes Technical FAQ

10. Delivery, Warranty and Customer Support

- Production & Delivery: Typical cycle: 7–15 days for standard specs, up to 20–25 days for custom/volume orders. Worldwide shipment with compliance documentation.

- Warranty: 2 years for rust-through or manufacturing defects, replace/repair policy applies.

- Support: 24/7 technical hotline, full installation guides, global on-site support available for major projects.

11. Summary: Why Choose Galvanized or Powder Coated Anti-Climb Protect Wall Spike?

- Superior durability & corrosion resistance (ISO/ASTM tested)—proven through client feedback and harshest outdoor applications.

- Certified, auditable, and easily integrated into existing perimeter systems for industrial, commercial, and residential clients.

- Customizable—matched to security needs and aesthetic requirements.

- Full compliance (ISO 9001, ANSI, EN13659), with robust warranty and reliable global supply chain.

- Backed by 15+ years of perimeter security experience, endorsed by leading engineering companies worldwide.

12. Authoritative References

- Grand View Research: Perimeter Security Market Analysis

- IFSEC Global: Perimeter Security in Oil & Gas

- Sage Journals: Evaluating Perimeter Security Solutions' Efficacy

- ASEC Security Forum: Fence Spike Technologies

- Official ANSI Standards Catalog

- ASTM B117 Salt Spray Test Standard

- ISO 9227:2017 Corrosion Tests in Artificial Atmospheres

Latest News

-

Metal Gully Grid 150mm: Durable Drainage Solutions for Modern Infrastructure

NewsNov.24,2025

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA