Corner Bead

A corner bead is a protective trim used in drywall installation to reinforce and finish the corners of walls. Typically made from materials such as metal, PVC, or paper-faced steel, corner beads are designed to provide a clean, sharp edge where two drywall panels meet at a corner. They help prevent damage to the corners from everyday wear and tear, such as bumps or abrasions, which can be common in high-traffic areas. The corner bead also helps to achieve a smooth, straight corner, improving the overall aesthetic of the wall and making it easier to apply finishing coats of joint compound. The bead is attached to the drywall with nails, staples, or adhesive, and once secured, the edges are covered with joint compound to create a seamless transition between the bead and the drywall. Corner beads are available in various profiles, including square, round, or bullnose, depending on the desired finish and look. In addition to protecting the corners, corner beads provide added strength to the drywall corner, making it more resilient to impacts and reducing the likelihood of damage over time. They are particularly useful in areas prone to physical contact, such as doorways, hallways, and corners of rooms. Using corner beads not only improves the durability of the drywall but also enhances the overall finish of the room. For those looking to achieve a high-quality, professional look, corner beads are an essential component in drywall installation, ensuring that corners are both structurally sound and visually appealing.

What Types of Corner Beads Are Available, And How Do You Choose the Right One for Your Project?

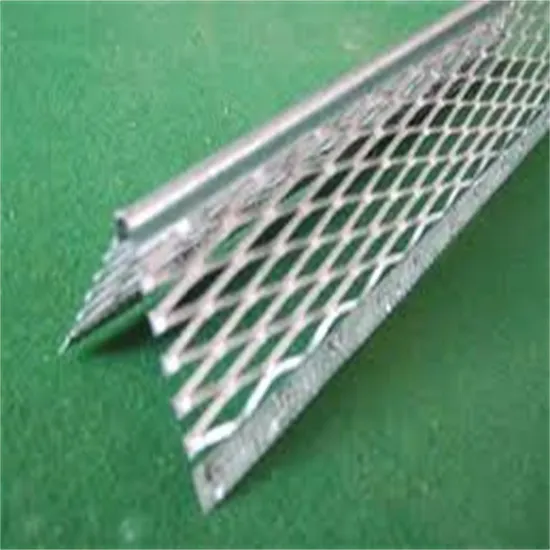

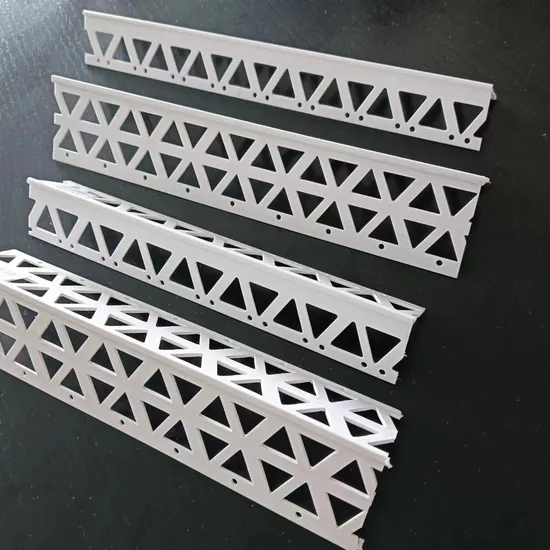

There are several types of corner beads available, each designed for specific applications and aesthetic preferences. The most common types include metal corner beads, PVC corner beads, paper-faced metal corner beads, and flexible corner beads. Metal corner beads, typically made from galvanized steel, are the most durable and are ideal for high-traffic areas where the corners may be subject to heavy use or impact. They provide excellent protection and strength, making them a popular choice for residential and commercial drywall installations. PVC corner beads are lightweight, corrosion-resistant, and offer ease of installation, making them a great choice for areas exposed to moisture or humid conditions, such as bathrooms or basements. They are also less prone to denting compared to metal beads, making them a practical option in environments where durability is key. Paper-faced metal corner beads combine the strength of metal with the ease of taping, as they come with a layer of paper tape that can be easily mudded over, offering a smoother finish. These are commonly used in both residential and commercial settings. Flexible corner beads are designed for curved or rounded corners, offering versatility for unique architectural designs where traditional corner beads may not be suitable. When choosing the right corner bead, it’s important to consider factors such as the location of the installation, the level of traffic the area will receive, the desired finish, and environmental conditions. For instance, in areas exposed to moisture, PVC or paper-faced corner beads may be more appropriate, while for high-impact areas, metal corner beads would be the most effective. Additionally, the type of finish desired, such as a rounded or square edge, will also dictate the best choice for the project.

How Do You Install a Corner Bead, And What Tools Are Needed for the Job?

Installing a corner bead is a straightforward process, but it requires some basic tools and preparation to ensure a clean and durable finish. The first step is to measure and cut the corner bead to the required length. If you're using metal corner beads, a metal cutting tool or snips can be used to achieve a precise cut. For PVC corner beads, a simple utility knife can be sufficient. Once cut, position the corner bead along the drywall corner, ensuring it is aligned with the edges of the panels. Most corner beads can be attached with nails, staples, or drywall adhesive, depending on the type. For metal corner beads, nails or staples are typically used to fasten the bead to the drywall, ensuring that the bead is securely in place. When using adhesive, apply a thin layer to the back of the corner bead before positioning it in place. Once attached, the next step is to apply joint compound over the bead. This is done using a drywall knife to spread a thin layer of compound over the bead, smoothing it out so that the corner bead blends seamlessly with the rest of the wall. After the compound has dried, sand the area to create a smooth, even surface. Repeat the process as needed to build up additional layers of joint compound and achieve the desired smooth finish. The final step is to paint or texture the corner to match the rest of the wall. Corner bead installation is a relatively simple DIY task, but for a professional-looking finish, it may be worth hiring a skilled contractor to ensure that the corners are perfectly aligned and the joint compound is applied smoothly.

What Types of Corner Beads Are Available, And How Do You Choose the Right One for Your Project?

There are several types of corner beads available, each designed for specific applications and aesthetic preferences. The most common types include metal corner beads, PVC corner beads, paper-faced metal corner beads, and flexible corner beads. Metal corner beads, typically made from galvanized steel, are the most durable and are ideal for high-traffic areas where the corners may be subject to heavy use or impact. They provide excellent protection and strength, making them a popular choice for residential and commercial drywall installations. PVC corner beads are lightweight, corrosion-resistant, and offer ease of installation, making them a great choice for areas exposed to moisture or humid conditions, such as bathrooms or basements. They are also less prone to denting compared to metal beads, making them a practical option in environments where durability is key. Paper-faced metal corner beads combine the strength of metal with the ease of taping, as they come with a layer of paper tape that can be easily mudded over, offering a smoother finish. These are commonly used in both residential and commercial settings. Flexible corner beads are designed for curved or rounded corners, offering versatility for unique architectural designs where traditional corner beads may not be suitable. When choosing the right corner bead, it’s important to consider factors such as the location of the installation, the level of traffic the area will receive, the desired finish, and environmental conditions. For instance, in areas exposed to moisture, PVC or paper-faced corner beads may be more appropriate, while for high-impact areas, metal corner beads would be the most effective. Additionally, the type of finish desired, such as a rounded or square edge, will also dictate the best choice for the project.

How Do You Install a Corner Bead, And What Tools Are Needed for the Job?

Installing a corner bead is a straightforward process, but it requires some basic tools and preparation to ensure a clean and durable finish. The first step is to measure and cut the corner bead to the required length. If you're using metal corner beads, a metal cutting tool or snips can be used to achieve a precise cut. For PVC corner beads, a simple utility knife can be sufficient. Once cut, position the corner bead along the drywall corner, ensuring it is aligned with the edges of the panels. Most corner beads can be attached with nails, staples, or drywall adhesive, depending on the type. For metal corner beads, nails or staples are typically used to fasten the bead to the drywall, ensuring that the bead is securely in place. When using adhesive, apply a thin layer to the back of the corner bead before positioning it in place. Once attached, the next step is to apply joint compound over the bead. This is done using a drywall knife to spread a thin layer of compound over the bead, smoothing it out so that the corner bead blends seamlessly with the rest of the wall. After the compound has dried, sand the area to create a smooth, even surface. Repeat the process as needed to build up additional layers of joint compound and achieve the desired smooth finish. The final step is to paint or texture the corner to match the rest of the wall. Corner bead installation is a relatively simple DIY task, but for a professional-looking finish, it may be worth hiring a skilled contractor to ensure that the corners are perfectly aligned and the joint compound is applied smoothly.