Jul . 30, 2025 05:40 Back to list

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

The ever-increasing demand for durable, cost-effective, and corrosion-resistant industrial materials has made galvanized grating pivotal in sectors such as petrochemical, metallurgy, construction, wastewater management, and more. This guide provides you with in-depth data, pricing, technology, and real-world cases for galvanized grating price, focusing on the Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling—one of the market’s most innovative and robust solutions.

Industry Trends in Galvanized Grating: Global Demand & Market Outlook 2024

According to the Global Steel Grating Market Analysis 2023-2028, the demand for galvanized steel grates has witnessed a CAGR of 5.6% owing to:

- Rise in infrastructure and industrial construction

- Stringent requirements for safety, anti-slip, and corrosion resistance in process industries

- Increased investment in wastewater treatment, oil & gas, energy, and transit facilities

As per Mordor Intelligence - Steel Grating Market Insights, Asia-Pacific continues to be the fastest-growing regional segment, with China, India, and Southeast Asia spearheading galvanized steel grating deployment.

Understanding Galvanized Steel Grate: Types, Structure, and Applications

Galvanized grating refers to a load-bearing lattice structure—typically made from carbon steel or stainless steel—that is hot dip galvanized after fabrication to acquire superior corrosion protection. Common terminologies you’ll encounter include:

- Galvanized Steel Grating: A metal grid with interconnected bearing bars and cross rods, galvanization prolongs lifespan

- Hot Dipped Galvanized Welded Grating: Grating welded and then submerged in molten zinc at 450°C—creating a metallurgically bonded zinc coating

- Press-Locked/Swaged/Forge-Welded Grating: Describes different fabrication processes impacting strength, price, and application

Galvanized Grating Price Trends: 2024 Data & Parameter Comparison

| Region | Type | Specification (mm) | Galvanizing | Standard | Galvanized Grating Price (USD/㎡) |

|---|---|---|---|---|---|

| Asia (China) | Welded | 25x3/30x3 | HDG ≥ 70μm | ISO 9001/1461 | $16–$22 |

| Europe | Press-Locked | 30x5/40x5 | HDG ≥ 85μm | EN 1090 | $24–$36 |

| North America | Swaged | 30x5 | HDG ≥ 100μm | ANSI/NAAMM MBG531 | $28–$42 |

| Middle East | Welded | 25x5 | HDG ≥ 65μm | BS 4592 | $18–$27 |

Note: Final galvanized grating price varies with raw material fluctuations, section profiles, zinc thickness, processing complexity, and logistics. Request custom quotations here.

Manufacturing Process of Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

[Certification: ISO9001, Mill Test Report]

[EN ISO 15614/15609 Certified]

[According to ISO 1461/FDA/ASTM A123]

Key Technical Parameters: Hot Dipped Galvanized Steel Grating vs Market Standards

| Parameter | Hot Dipped Galvanized Welded Metal Grid | Pressed/Swaged Grating | Uncoated Steel Grating |

|---|---|---|---|

| Material Grade | Q235/SS400 | S235JR/Q195/Q345 | Low Carbon Steel |

| Galvanizing (μm) | 99–135μm (Avg:120) | 70–110μm | None |

| Recommended Span (m) | 1.2–7.2 | 1.2–6.5 | 1.0–4.0 |

| Slip Resistance | R12–R13 (EN 51130) | R10–R12 | R9 |

| Surface Treatment | HDG | HDG/Electrolytic | None |

| Lifespan (Years, C5 Env.) | ≈ 45–60 | 35–50 | < 8 |

| Maintenance | Low | Medium | High |

| Standard Compliance | ISO1461, ASTM A123, EN1090 | EN1090, NAAMM MBG 531 | NAAMM MBG 531 |

Applications & Advantages of Galvanized Grating in Industrial Projects

- Oil & Gas Platforms: Anti-slip walkways, pipe bridges, trench covers—saving up to 60% in maintenance VS non-galvanized grid (Source: Offshore Technology).

- Wastewater Treatment Plants: Flooring, aerial maintenance pathways—resist up to 25 years of chemical exposure, no repainting needed.

- Metallurgy & Mining: Conveyor trench covers, pit covers, stairs—high mechanical strength and impact resilience.

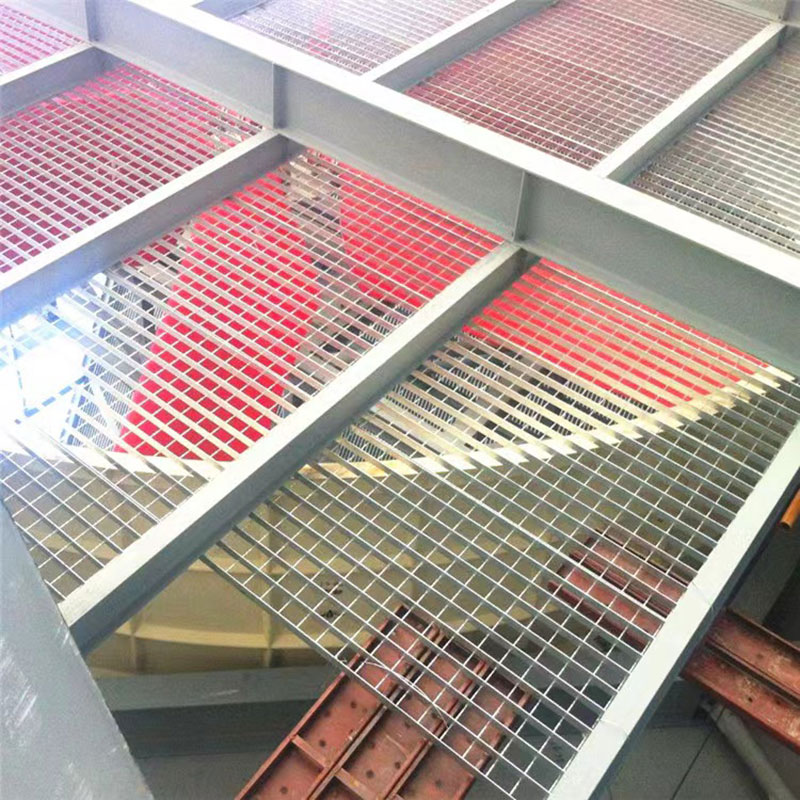

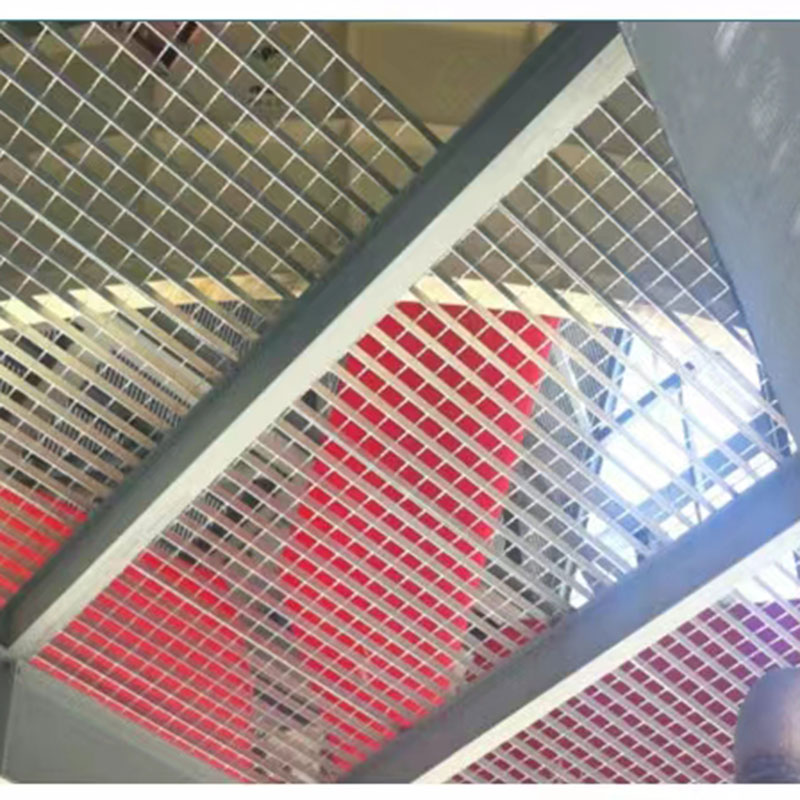

- Architecture: Ceiling features, facade/curtain wall, parking floors—modern aesthetic, high permeability to light and air.

- Chemical Plants: Corrosion resistance in acid/alkali splash zones—conform to EN 1090, FDA-standard workplaces.

Case Study: In 2023, a Southeast Asian petrochemical facility upgraded all floor walkways to galvanized steel grating; measurable outcomes: zero corrosion failures after 14 months, 40% drop in slip injuries (EN ISO 14122 compliance).

Technical Advantages & Manufacturer Comparison: Why Choose Us?

Chengsen’s Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling stands out due to:

- Adherence to ISO 1461, ASTM A123, EN 1090—ensuring global compatibility

- Advanced CNC welding & precision edge trimming for seamless fit

- High zinc layer (avg 120μm)—industry-leading corrosion protection

- Comprehensive in-house testing: salt spray, load & bonding strength, micro-thickness

- Customizable mesh sizes (22x22 / 30x100mm), thickness (3–8mm), finishes (serrated/plain)

- Long lifecycle with low total cost of ownership

| Manufacturer | Certifications | Custom Service | Avg. Zinc Layer (μm) | Annual Output (tons) | Delivery (days) |

|---|---|---|---|---|---|

| Chengsen | ISO1461, EN1090, CE, SGS | Yes | 120 | 25,000 | 12–18 |

| Yantai GrateTech | ISO9001, EN1090 | Limited | 90 | 18,000 | 18–24 |

| US Grid-Fab | ANSI MBG531, FM, UL | On request | 100 | 11,000 | 22–35 |

| EuroBar Grating | EN1090, CE | Yes | 100 | 9,800 | 28–35 |

Custom Solutions: Tailor-Made Galvanized Grating for Your Projects

Chengsen offers one-stop ODM/OEM solutions from CAD design, prototyping to on-site consultancy—ideal for non-standard mesh, special coatings (epoxy, anti-static), unique load demands, and challenging architectural geometries.

- Free Design: Submit project drawings, receive professional layout (DWG/STEP) in 2–3 days

- Sample Fabrication: Fast-track samples (3–5 days) for prior performance inspection

- On-Site Measurement: For large/complex projects, expert engineers dispatched globally

Frequently Asked Questions (FAQ) on Galvanized Steel Grating

Delivery, Warranty & Support: Your Trusted Galvanized Grating Partner

ISO1461, EN1090, CE, SGS, ASTM A123

2 Years Product Guarantee, Complaint Rate <0.5%

Standard: 12–18 days

Custom: 20–28 days

24/7 Engineering & Logistic Inquiry, Free Consultation

CNPC, Linde, Mitsubishi, MCC, Veolia

All grating galvanized products are traceable, with third-party test reports available. Our galvanized grating price is always backed by transparent calculation and compliance with international standards.

Further Reading & Authoritative Resources

- NAAMM Metal Bar Grating Manual: naamm.org/mbg-manual

- Galvanizers Association Standards: galvanizing.org.uk

- Stainless Steel World Forum on Industrial Gratings: stainless-steel-world.net

- ResearchGate – Comparative Study on the Corrosion Protection of Galvanized Steel Grating: researchgate.net

- Civil Engineering Forum & Discussions: eng-tips.com

Stay updated with the latest standards and user experience on major industry forums and reputable journals referenced above.

Latest News

-

Metal Gully Grid 150mm: Durable Drainage Solutions for Modern Infrastructure

NewsNov.24,2025

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA