Jan . 09, 2025 12:09 Back to list

stainless steel wire mesh conveyor belt

Authoritativeness in this field is reflected in the fabricator’s ability to set industry standards and influence trends. Associations with professional organizations, contributions to scholarly articles, and active participation in industry conferences establish a fabricator's credibility. An authoritative wire mesh fabricator doesn’t just follow established norms – they define them. By leading the way in developing new techniques and adopting sustainable practices, authoritative fabricators inspire trust and lead by example. Companies seek out these leaders for their ability to deliver products that not only meet expectations but push boundaries. Trustworthiness is the foundation upon which long-term business relationships are built, particularly in the wire mesh fabrication industry where precision and reliability are non-negotiable. Transparent business practices, adherence to deadlines, and consistent communication are hallmarks of a trustworthy fabricator. Furthermore, a commitment to quality assurance, demonstrated through certifications and rigorous testing protocols, reassures clients that their fabricator prioritizes product integrity and safety. Wire mesh projects often involve significant investments, and trust in one’s fabricator ultimately reduces risk and facilitates smoother project execution. In summation, a proficient wire mesh fabricator encompasses the four essential pillars of experience, expertise, authoritativeness, and trustworthiness. These qualities not only set the standard for exemplary service delivery but also ensure that every project, no matter the scale, is executed with precision and professionalism. Choosing the right fabricator means aligning with a partner whose craftsmanship and ethical practices drive mutual success and innovation.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

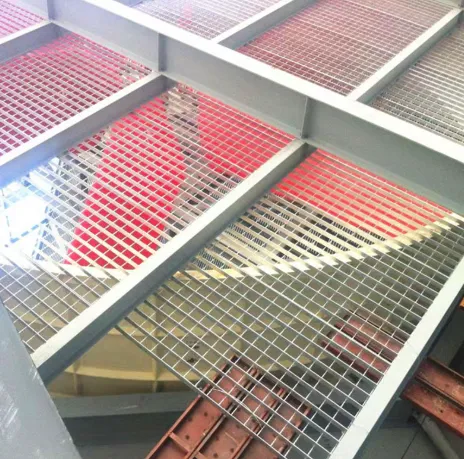

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA