Jan . 09, 2025 11:21 Back to list

wire mesh fabricators

Trustworthiness is the cornerstone of long-term relationships between wire mesh fabricators and their clientele. Transparent business practices and a track record of delivering on promises enhance their credibility. Client testimonials and case studies serve as powerful endorsements of their reliability. Many fabricators offer warranties and post-installation support, ensuring that any issues are promptly addressed. This builds confidence among clients, knowing they are partnering with a company that stands by its products. In such a competitive landscape, wire mesh fabricators constantly innovate to remain at the forefront. Advanced technologies like automated weaving machines and laser cutting are integrated into the fabrication process, resulting in higher precision and efficiency. Furthermore, sustainable practices are increasingly being adopted. Fabricators are exploring environmentally friendly coatings and recycling programs, demonstrating a commitment to reducing environmental impact alongside stellar product performance. As the demand for wire mesh products grows globally, the role of experienced, expert, authoritative, and trustworthy fabricators becomes ever more critical. They are not just suppliers, but partners in project success, offering insights and solutions that are pivotal in shaping durable and efficient infrastructures. Their work forms the backbone of a multitude of applications, seamlessly balancing form and function. Through unwavering dedication to excellence, these fabricators play a pivotal role in building a resilient future.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

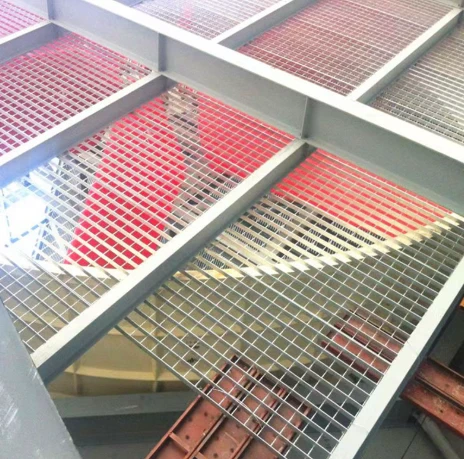

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA