Feb . 05, 2025 03:48 Back to list

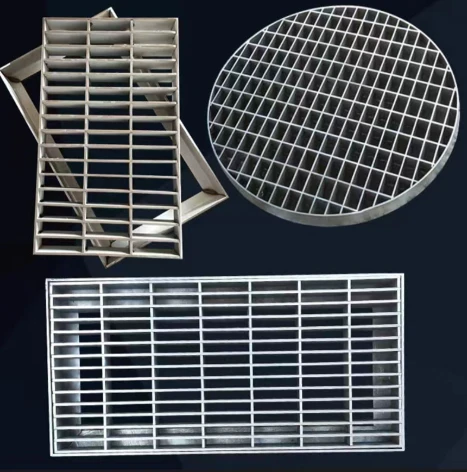

galvanized steel grating

Moreover, trustworthiness is critical when discussing welded steel grating, especially concerning compliance with stringent industry standards. Various international standards, such as those outlined by the American National Standards Institute (ANSI) and European Committee for Standardization (CEN), ensure that grating manufacturers meet rigorous quality and safety requirements. Adherence to these regulations guarantees that products consistently meet consumer and industry expectations. Real-life applications further illustrate the value of welded steel grating. For instance, in urban planning, these gratings aid in creating sustainable drainage solutions by facilitating effective water runoff, minimizing the risk of flooding. Additionally, their robust structure supports vehicular and pedestrian traffic, ensuring safety and reliability in public spaces. Anecdotal evidence from industry professionals supports the grating's positive impact on project outcomes. Engineers have reported reductions in maintenance costs attributable to its durability, as well as improvements in workplace safety resulting from its non-slip surface options. These factors contribute substantially to cost-effectiveness over the lifespan of a project, enhancing investment returns. In conclusion, the inclusion of welded steel grating in your project offers numerous benefits due to its strength, adaptability, and compliance with safety standards. Its broad application spectrum, from industrial machinery platforms to sophisticated architectural designs, demonstrates its versatility. The assurance provided by industry standards and real-world applications reinforces its status as a trusted material choice, ensuring that it continues to be a preferred selection for current and future construction endeavors.

Latest News

-

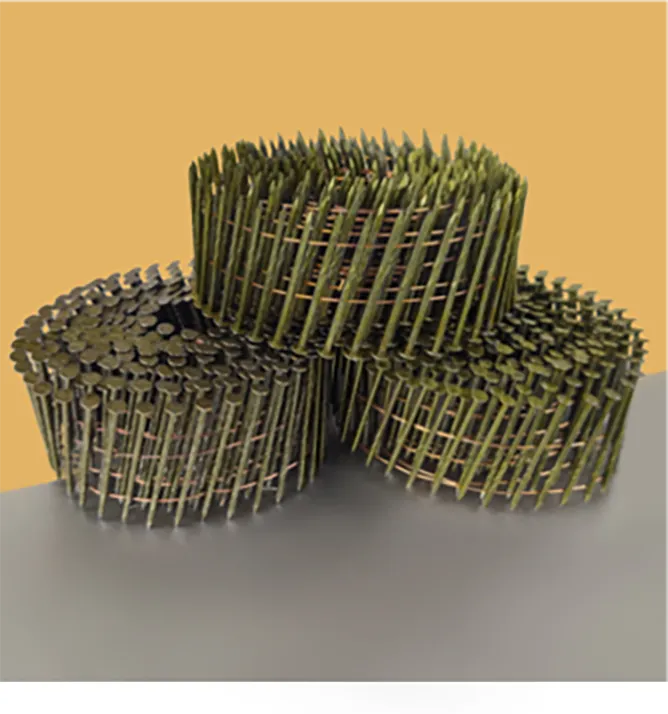

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA