Feb . 05, 2025 03:24 Back to list

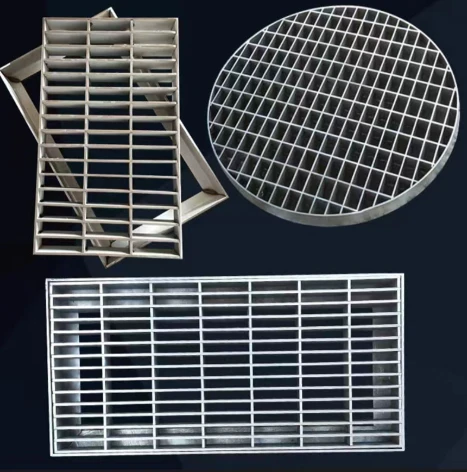

galvanized grating

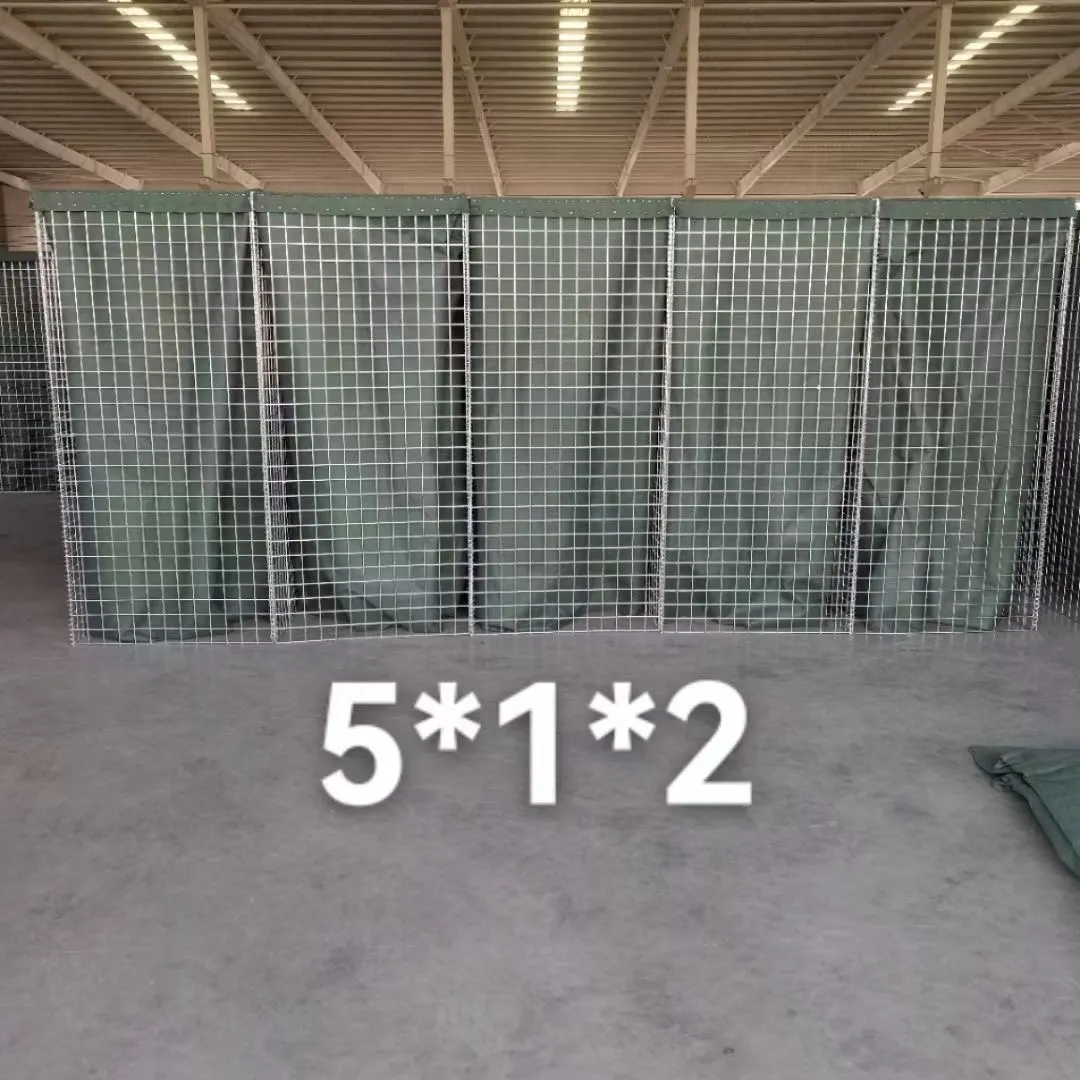

From a material expertise perspective, it's worth noting the adaptability of galv grating in diverse architectural and infrastructural designs. Its aesthetic appeal, combined with functional benefits, makes it suitable for modern architectural projects. For example, urban architects select galvanized grating for designing open-air structures that require effective drainage and ventilation without compromising on design integrity. This application extends beyond practical usage, as architects use it aesthetically to enhance the modern and industrial look of a space. For authoritative sources like industry standards and construction guidelines, galv grating's compliance with standards such as ASTM A123 for zinc coatings is vital. Such standards guarantee the quality and performance of the product, which in turn fosters trust with engineers, architects, and construction clients. The assurance of quality compliance underscores its credibility as a material choice among industry professionals. Anecdotal evidence and case studies further highlight the trustworthiness of galvanized grating. Numerous projects worldwide have testified to its reliability and efficiency, from public infrastructure in bustling metropolitan areas to platforms in remote industrial setups. Testimonials from project managers and engineers often emphasize the reduction in long-term costs and maintenance hassles, reinforcing the value galv grating brings to projects demanding long-term returns on investment. In conclusion, galvanized grating is not merely a product but a pivotal solution for modern construction and industrial demands. Its balance of durability, safety, and adaptability across various applications ensures its status as a trusted component in engineering projects. As industries evolve to meet new challenges, the demand for reliable materials like galv grating is set to grow, offering industries a material that not only meets but exceeds expectations.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA