Jan . 17, 2025 05:04 Back to list

Floor Drainage Trench Cover For High Quality Stainless Steel Serrated Steel Grating

Another authoritative insight is the importance of customization and installation. Installation of steel grids should not be underestimated, as improper installation may lead to misalignment, reduced efficiency, and even hazards. Working with reputable manufacturers and experienced professionals ensures that the grids are tailored to fit seamlessly within the existing infrastructure. Moreover, customized solutions can capitalize on innovative technology such as anti-slip surfaces, which are increasingly in demand for safety-conscious organizations. In terms of trustworthiness, consistent performance and compliance with industry standards are non-negotiable. Authentic and certified steel grids not only adhere to safety and quality benchmarks but also instill confidence among end-users and stakeholders. Trust is further enhanced when manufacturers provide warranties and post-installation support, addressing concerns and minimizing downtime in case of unforeseen issues. When selecting a steel grid for drainage, the multifaceted nature of the decision becomes apparent. The right choice involves a delicate balance of technical specifications, user requirements, safety standards, and long-term costs. Although the initial investment in quality steel grids may be higher, the reduction in maintenance and the increase in safety and performance make them a cost-effective solution over time. Ultimately, the integration of steel grids into drainage systems underscores a broader commitment to sustainable urban development. With global weather patterns becoming more unpredictable, effective drainage solutions are central to mitigating urban flooding risks and enhancing community resilience. Adapting to this evolving landscape requires reliance on experienced professionals, high-quality materials, and innovative solutions — a synergy perfectly embodied by the strategic use of steel grids in modern drainage systems. In conclusion, steel grids for drainage are a sophisticated component of civil infrastructure projects, offering unparalleled strength, safety, and durability. By understanding the intricacies of their design, function, and application, stakeholders can make informed decisions that align with both current challenges and future aspirations in urban planning.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

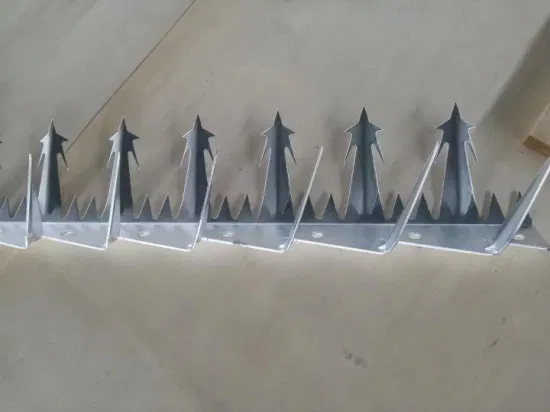

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA