Jan . 31, 2025 02:14 Back to list

serrated steel flat bar

Authoritativeness stems from the endorsements and certifications these products often boast. Many industries adhere to stringent ISO standards, which serrated steel flat bars typically meet or exceed. Such standards ensure that the bars are consistently safe and reliable, reinforcing the manufacturer's reputation in the marketplace. Industry thought leaders often cite standards such as ASTM A36 for carbon steel flat bars or ASTM A240/A480 for stainless steel alternatives, providing a benchmark for quality that's recognized globally. Trustworthiness is crucial, particularly in applications where safety is paramount. Customers and end-users of serrated steel flat bars place immense trust in the manufacturers to supply products that perform as promised without failure. This trust is often earned through transparent business practices, excellent customer service, and robust testing procedures that guarantee each batch meets the rigorous demands of real-world environments. Additionally, partnerships with leading industry bodies further establish credibility, as these affiliations signify a commitment to upholding industry best practices. The environmental impact of serrated steel flat bars cannot be overlooked. As sustainability becomes a priority, many companies are shifting towards eco-friendly manufacturing practices. Recycling plays a pivotal role in the lifecycle of these steel bars, where scrap metals are reprocessed to produce new bars, thus reducing the demand for raw materials. Some manufacturers have taken bold steps to incorporate eco-friendly practices by minimizing energy use during production and reducing carbon emissions, setting a standard for others to follow. Conclusively, serrated steel flat bars are more than just industrial components; they are a testament to meticulous engineering, adherence to quality standards, and a commitment to safety. Their widespread use in industries such as construction, manufacturing, and transportation underscores their value. By sharing experiences and emphasizing professional manufacturing processes, industries are better equipped to select the right serrated steel flat bars to meet their needs—ensuring that safety, performance, and sustainability are always prioritized.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

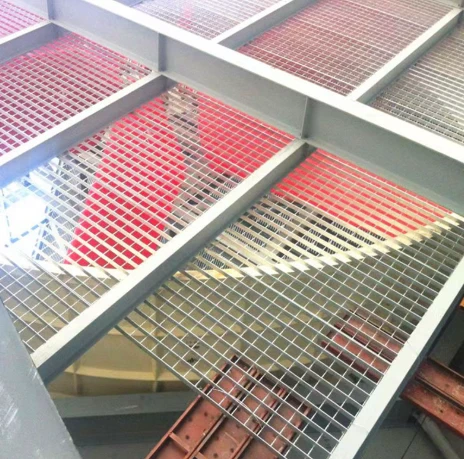

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

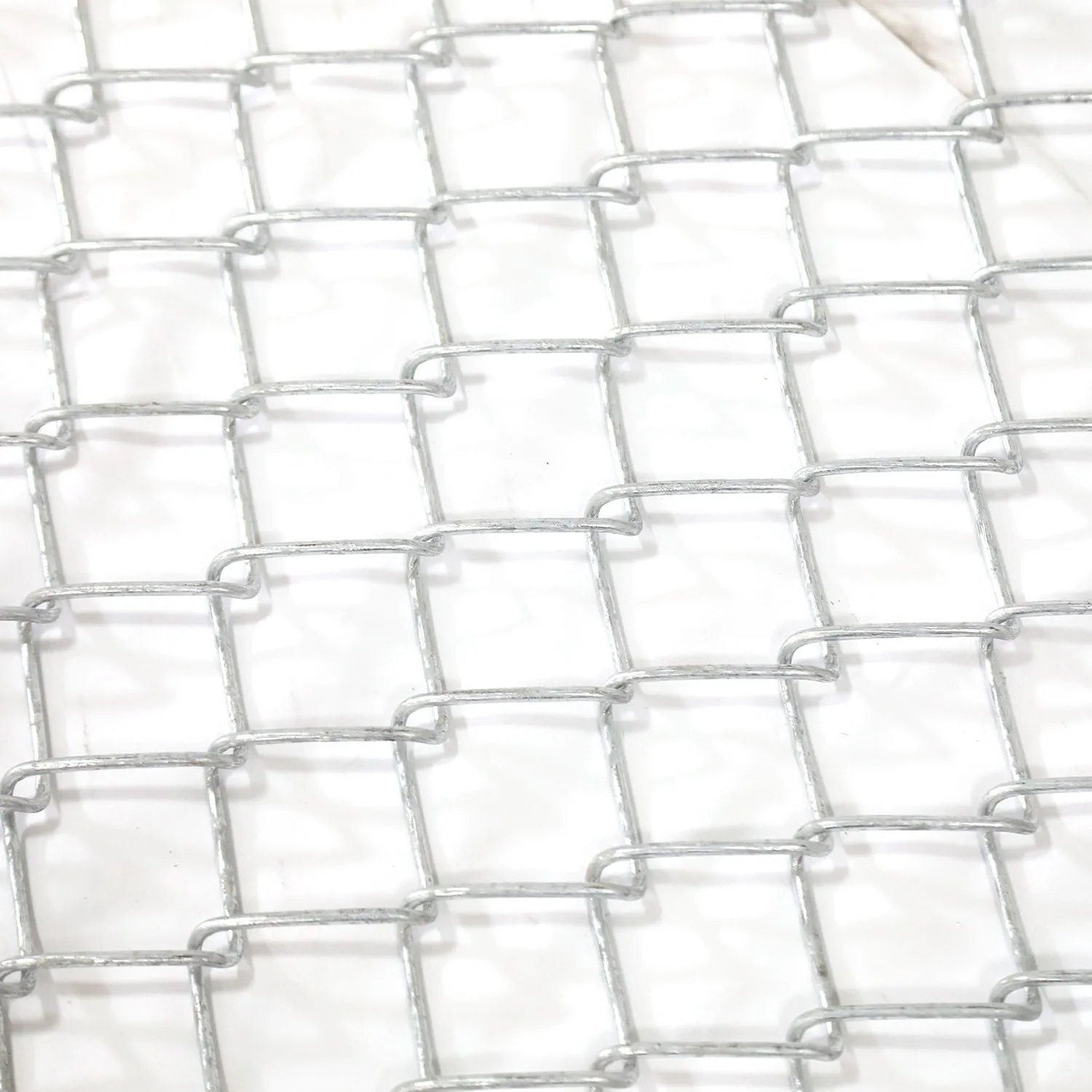

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA