Jan . 31, 2025 01:50 Back to list

serrated steel bar

Authoritativeness in the construction industry often hinges on endorsements and ratings from reputable agencies. Serrated steel bars have consistently gained approval from leading international bodies that regulate construction materials. These endorsements affirm their compliance with stringent quality and safety standards, making them a preferred choice for landmark constructions—ranging from skyscrapers to bridges. By incorporating feedback from real-world applications and industry experts, manufacturers continue to innovate, refining serrated steel bars to adapt to new challenges and exceed performance expectations. Trustworthiness is a key concern for any construction project, affecting both short- and long-term outcomes. Serrated steel bars provide an added layer of credibility through documented performance records and certifications. Project managers and stakeholders often seek assurance that their investments in construction materials will yield immediate and enduring results. The documented success stories and extensive case studies available for serrated steel bars serve as powerful testimonials of their reliability. These bars have been utilized in a multitude of high-stakes projects, consistently proving their worth in demanding conditions, which fosters trust among all stakeholders involved. In conclusion, serrated steel bars represent a convergence of innovation, science, and practical application, setting a new benchmark in construction materials. Their ability to provide enhanced structural stability and performance assurance positions them as an unrivaled choice for modern construction needs. As these bars continue to gain traction in the industry, they exemplify the principles of experience, expertise, authoritativeness, and trustworthiness. For developers and engineers striving to merge safety with ingenuity, serrated steel bars offer the optimal solution—a testament to advanced engineering and design principles aimed at creating enduring and resilient structures.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

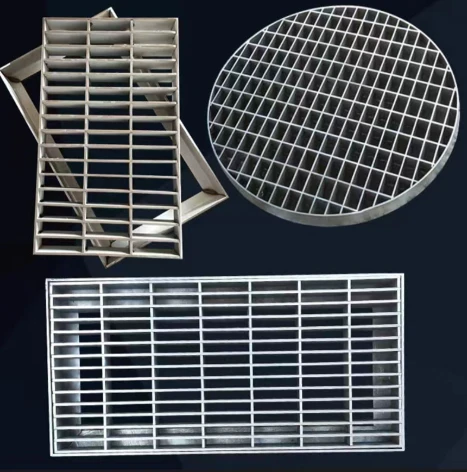

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA