Jan . 25, 2025 22:52 Back to list

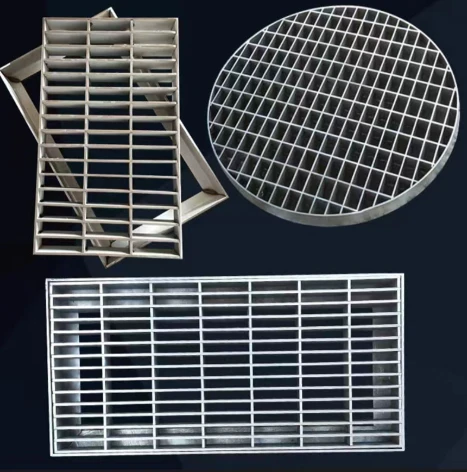

serrated steel grating

Numerous case studies highlight the benefits derived from the adoption of serrated galvanized steel grating. In the petrochemical sector, facilities have reported a marked decrease in slippage incidents post-installation, enhancing both safety records and operational efficiency. Meanwhile, in the infrastructure domain, municipalities have successfully employed this grating in pedestrian walkways and drainage covers, leveraging its robustness and adaptability to different urban environments. Sustainability remains a pivotal consideration in the contemporary industrial arena, and serrated galvanized steel grating does not disappoint. Beyond its durability, which reduces replacement frequency and waste, the grating is fully recyclable. The steel and zinc used are materials that can be reclaimed and reused, aligning with global recycling initiatives and making it a responsible choice for companies committed to green practices. In terms of expertise, manufacturers of serrated galvanized steel grating invest heavily in research and development to refine product offerings and anticipate future industry needs. Engaging with these manufacturers presents opportunities to collaborate on innovative solutions, whether through custom designs, enhanced material properties, or integration with smart technology for monitoring and maintenance purposes. Finally, trustworthiness is cemented through the extensive use of this grating by numerous high-profile industries worldwide. Testimonials from clients consistently emphasize its reliability and performance, fostering a reputation that new users can confidently rely upon. Safety certifications and compliance with international standards further attest to its quality, forming a strong foundation for trust among users and stakeholders. In conclusion, serrated galvanized steel grating represents an intersection of cutting-edge engineering, safety, and sustainability. Its impact cuts across industries by offering solutions that not only meet but exceed expectations. For those seeking a trustworthy, expert-approved option for industrial and commercial applications, this grating is a choice grounded in proven excellence and forward-thinking innovation.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA