Feb . 19, 2025 09:23 Back to list

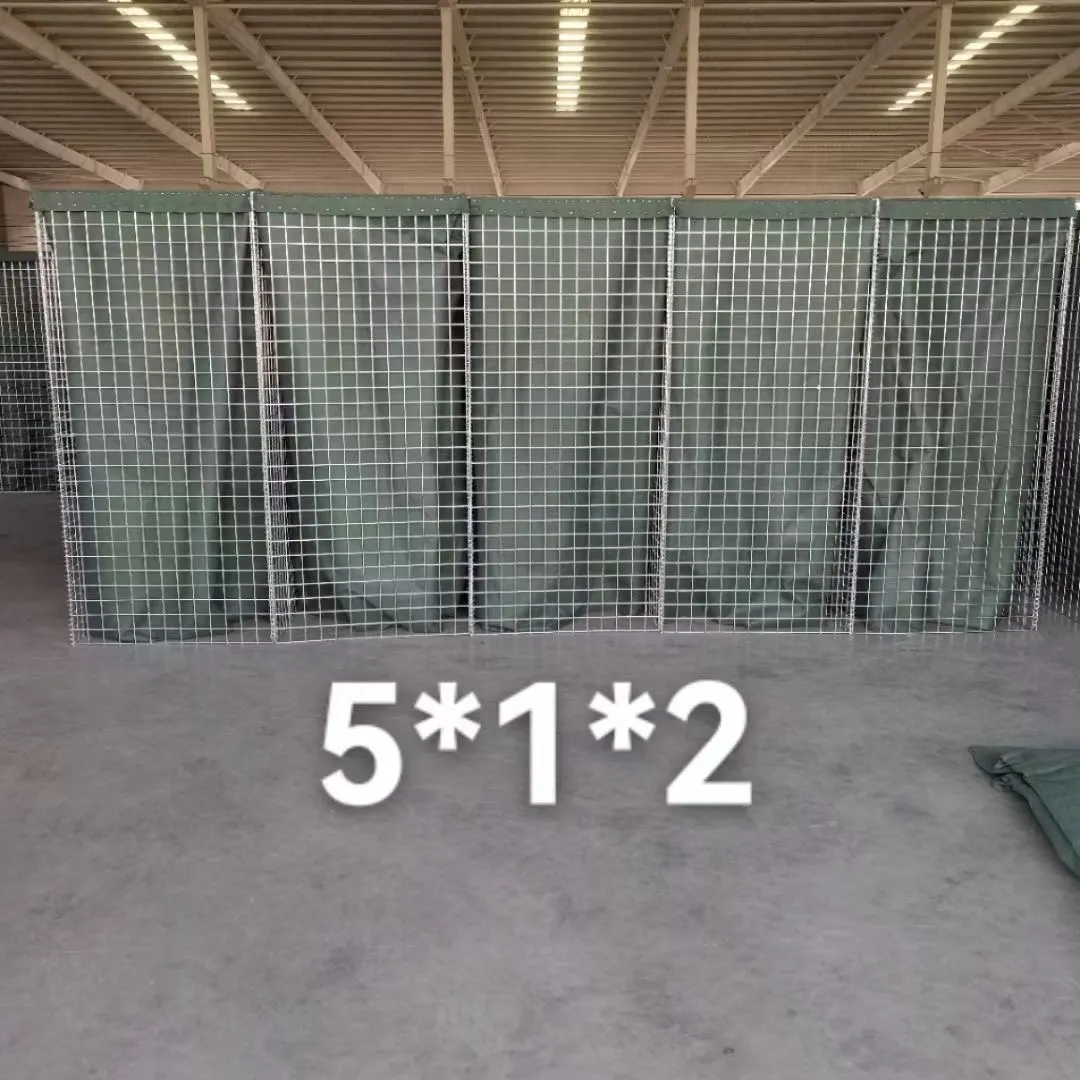

plastic coated wire panels

In terms of installation, plastic coated wire panels offer significant advantages as well. Due to their lightweight nature and pre-coated protection, they are easier and safer to handle compared to traditional metal panels. This not only reduces installation time but also minimizes labor costs, making them an economical choice for large-scale projects. Their low maintenance requirements further enhance their cost-effectiveness over their lifecycle, with most panels requiring no more than a simple cleaning to maintain their appearance and performance. Industry experts also highlight the environmental benefits of choosing plastic coated wire panels. Many manufacturers now prioritize sustainable practices in the production and recycling of these panels. The longevity and recyclability of the materials reduce the environmental impact, aligning well with the growing demand for eco-friendly building materials. As with any product, ensuring trust and reliability when choosing a supplier or manufacturer is paramount. Expert advice suggests verifying credentials and seeking third-party certifications to guarantee that the plastic coated wire panels meet industry standards and safety requirements. Partnering with reputable providers assures customers receive a high-quality product that performs as expected, thereby fortifying the trustworthiness of their investment. To sum up, plastic coated wire panels offer a compelling blend of durability, versatility, and aesthetic appeal, making them an ideal choice across various sectors. Their ability to endure harsh environmental conditions without compromising structural integrity is unmatched. By choosing the right type of coating and trusted suppliers, users can significantly enhance both the longevity and efficiency of their projects. As the demand for innovative, sustainable building solutions persists, plastic coated wire panels stand out as a commendable option for modern construction needs.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA