Feb . 19, 2025 09:00 Back to list

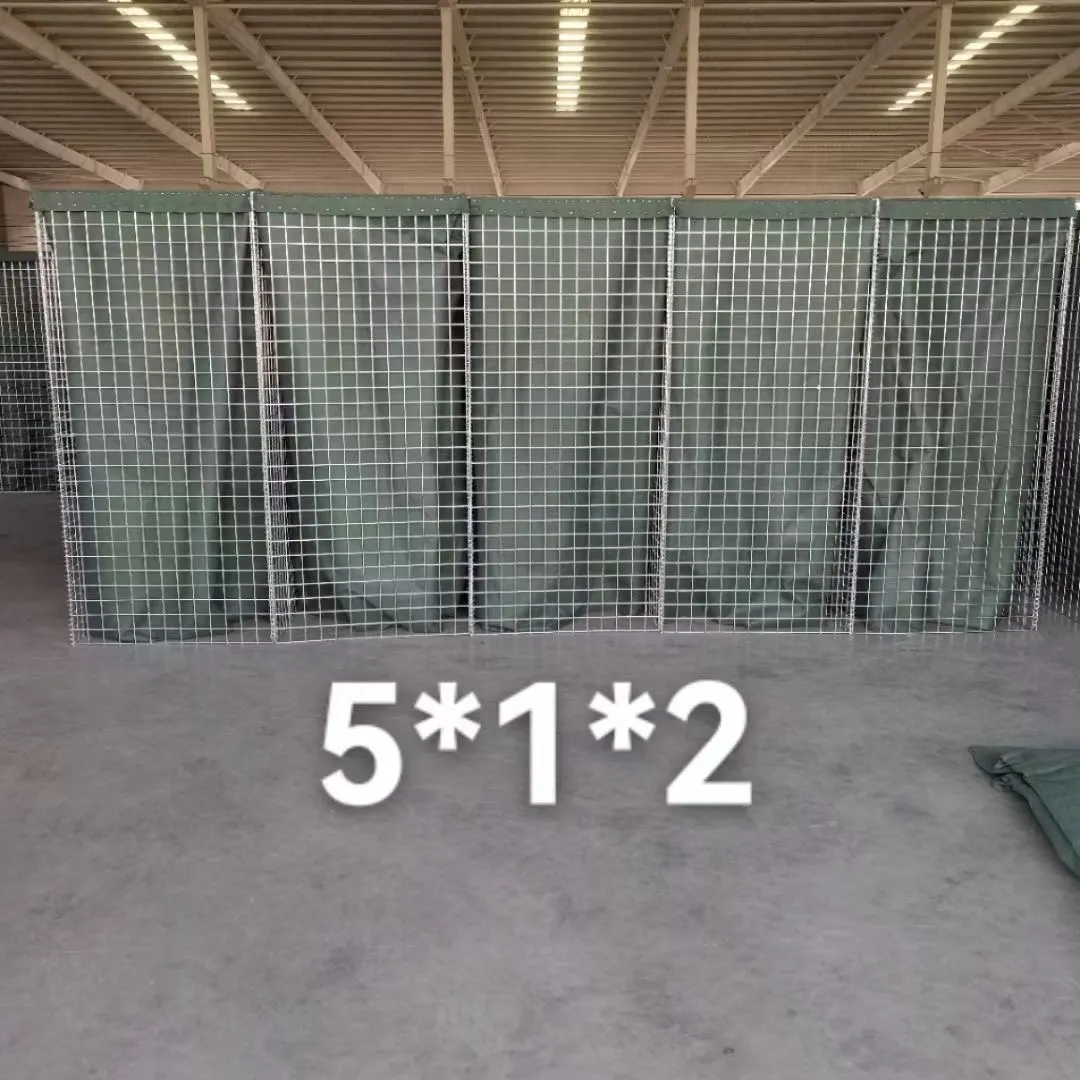

plastic coated wire mesh sheets

Credibility in the construction sector is also bolstered by the use of plastic coated wire mesh sheets. When used in building facades or masonry work, they provide essential structural support while also preventing rust and corrosion over time. This adaptability means that architects and builders can trust these materials to yield both functional and aesthetic benefits, aligning with modern sustainability goals due to their recyclability. In terms of safeguarding assets, security-conscious businesses and homeowners are increasingly opting for plastic coated wire mesh sheets. These meshes are perfect for securing perimeters, offering a visual deterrent with enhanced durability. The added plastic coating reduces the risk of tampering, ensuring an added layer of safety that traditional wire meshes lack. Environmentally, the application of plastic coated wire mesh sheets is a responsible choice. Provided they are sourced from reputable manufacturers adhering to environmental regulations, these meshes can be a part of eco-friendly projects. As they are often recyclable, their lifecycle contributes to sustainable practices, making them appealing to green-conscious consumers and industry experts alike. In summary, the integration of plastic coated wire mesh sheets into various sectors marks a significant step forward in material technology. Their capacity to deliver superior performance, coupled with their versatility and environmental benefits, underscores their authority in the market. For decision-makers seeking reliable, long-lasting solutions, embracing these innovative materials not only enhances project outcomes but also establishes a benchmark in quality and sustainability. As an evolving product category, the widespread acceptance and implementation of plastic coated wire mesh sheets illustrate a step towards more advanced, efficient, and responsible usage in multiple fields.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA