Jan . 16, 2025 02:34 Back to list

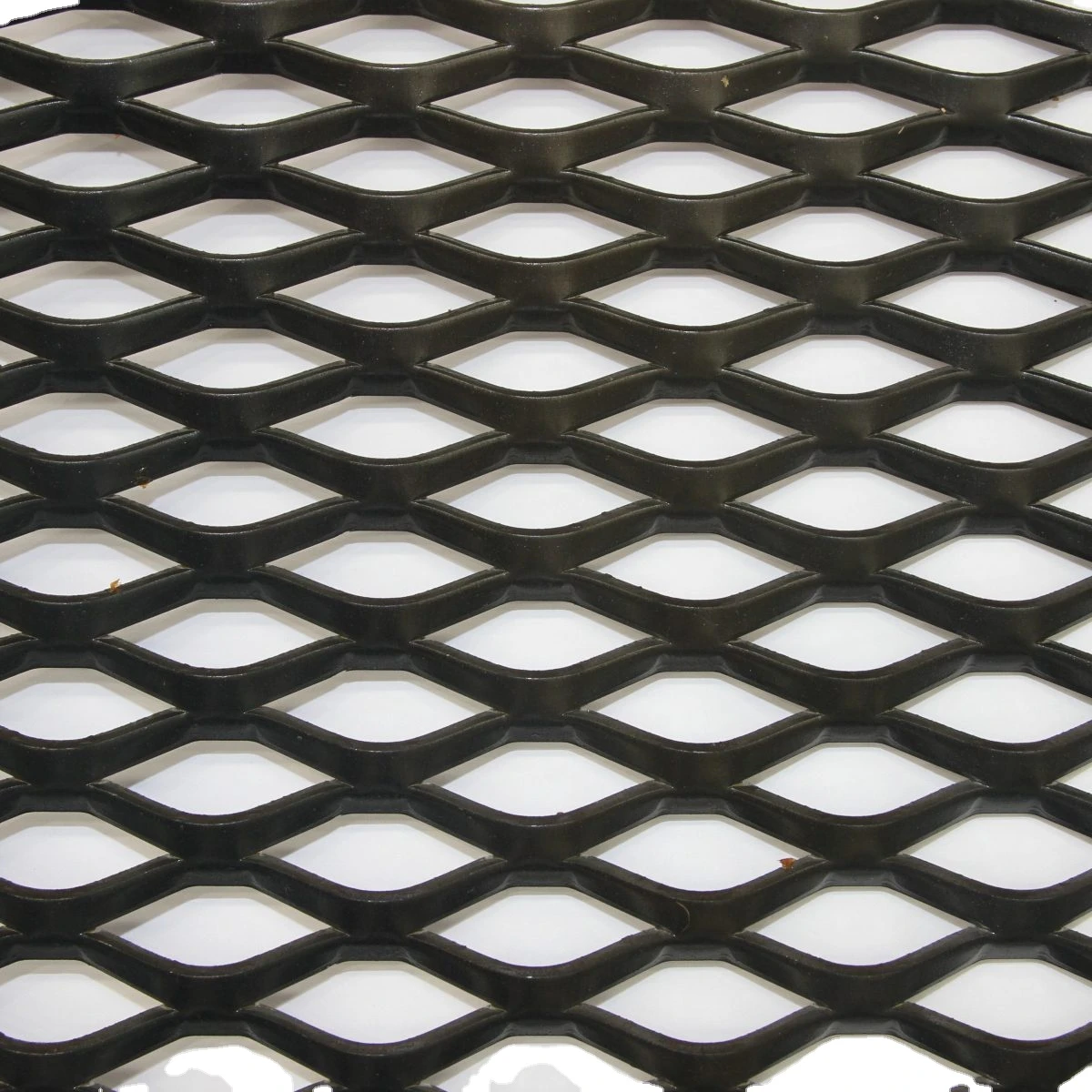

trench drain grate

Expertise in installation is equally important to ensure the effectiveness of metal drain grids. Precision in installation minimizes loose fittings and structural weaknesses, which can become safety hazards over time. Professional insights suggest collaborating with engineers during the planning phase to address specific site variables such as soil type, load requirements, and hydrodynamic considerations. These factors can significantly influence the grid's performance and life span, underscoring the necessity of integrative planning and consultation during the preliminary design stages. Authoritative voices in the industry also stress the importance of compliance with local regulations and standards. For instance, grids must adhere to load class specifications outlined in standards like EN 124 or ASME guidelines to ensure safety and functionality. Non-compliance not only risks public safety but can result in costly legal ramifications. Trustworthiness in a product is derived not only from its material and design but also from the manufacturer’s reputation. Reliable manufacturers invest in rigorous testing and quality assurance processes, offering certifications and warranties that reflect their commitment to excellence. Engaging with trusted brands, supported by positive reviews and testimonials from credible professionals, is often a decisive factor for stakeholders choosing metal drain grids. In conclusion, selecting the appropriate metal drain grid involves a multi-faceted approach encompassing material choice, professional installation, compliance with standards, and manufacturer reputation. By prioritizing these factors, stakeholders can optimize the functionality and longevity of their infrastructure projects, ensuring that these installations serve their purpose effectively for years to come. Leveraging both hands-on experience and industry expertise guarantees that the chosen solution is not only efficient but also safe and reliable, enhancing the overall trust in the constructed infrastructure.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA