Feb . 08, 2025 06:18 Back to list

High Quality Angle Bead Wire Mesh Aluminium Corner Bead for Sale

L-shaped beading also demonstrates exceptional versatility across various applications. For instance, it can serve as a decorative element on mirror frames or as finishing for shelving units. In commercial spaces, L-shaped beading is often used to enhance the architectural details of office furniture, lending a polished, professional look that aligns with the brand's identity. Authoritative voices in the field often highlight how L-shaped beading can impact environmental sustainability. By protecting furniture and fixtures, they extend the lifespan of these items, ultimately reducing waste and promoting a more sustainable approach to interior design. Many manufacturers now offer L-shaped beading made from recycled materials, aligning with the growing demand for eco-friendly building practices. When considering the purchase of L-shaped beading, consumers should seek products from reputable suppliers who provide detailed product specifications and certify the quality of their materials. Trust in the product is built through transparent practices, such as sourcing information and customer reviews, which offer insights into the product's real-world performance. In conclusion, L-shaped beading is more than a functional component; it is an art form that requires skill in selection, application, and maintenance. Its contribution to both the aesthetic and protective aspects of a project underlines the importance of incorporating expert knowledge into every phase of its use. As L-shaped beading continues to evolve and adapt to the needs of the modern consumer, it remains a symbol of enduring quality and craftsmanship in interior design.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

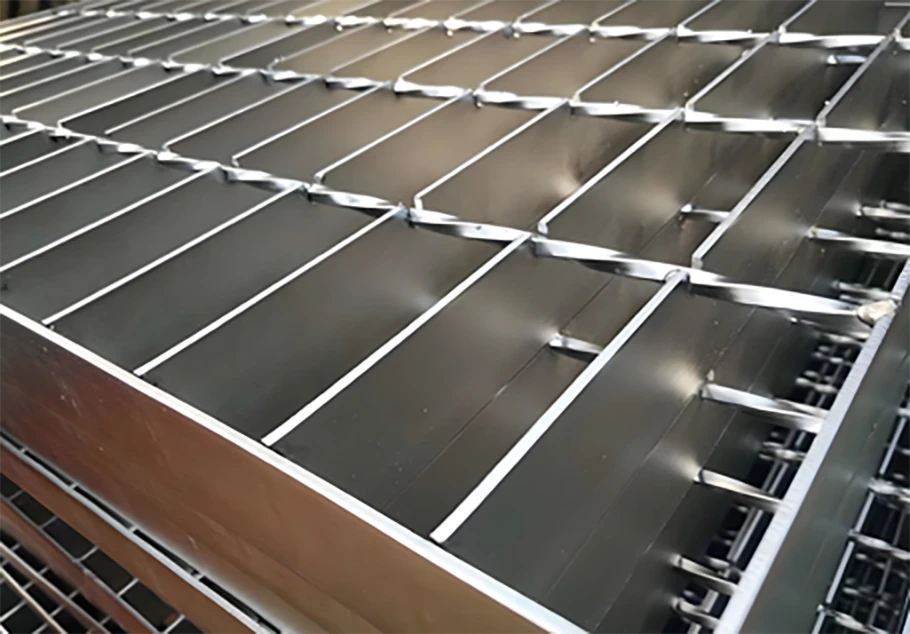

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA