Jan . 21, 2025 05:00 Back to list

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

3. Surface Treatment Finish treatments protect gratings from wear and environmental factors. While untreated gratings are more cost-effective initially, adding anti-slip coatings, paint, or galvanizing will enhance their longevity and performance, justifying a slight increase in price. 4. Manufacturing Process Technique variations, like welded or press-locked construction, impact labor costs, thereby affecting the overall price. Premium manufacturing processes ensure high-quality joints and surface uniformity, which are crucial for safety compliance in critical applications. Understanding the Real Value Experience and Expertise Setting an appropriate budget requires understanding the overall value beyond price. Consumers and industry professionals should consider factors like lifespan, maintenance requirements, and safety ratings. Gratings with proper certifications and industry-standard compliance may cost more but offer peace of mind and reduced liability risks, ultimately proving cost-effective in the long run. When planning for grating installation, it's wise to consult with experienced industry professionals. Expertise in grating selection ensures the chosen materials and specifications align with operational demands and environmental conditions. Collaborative planning with a qualified engineer or contractor can prevent costly over-specifications and ensure compliance with regulatory standards. Authoritative Insights into Grating Suppliers Choosing a grating supplier presents challenges due to the flooded market. Trustworthy suppliers provide detailed product specifications, certifications, and customer testimonials. Consider suppliers who demonstrate transparency in pricing models and offer comprehensive warranties. An established reputation and industry endorsements are strong indicators of reliability and product quality. Research and Review Ensuring Trustworthiness Invest time in researching and reviewing potential grating solutions. Customer reviews offer authentic insights into the performance and longevity of different grating options. Online platforms and industry forums facilitate discussions that could highlight subtle advantages or disadvantages of specific material choices. In conclusion, understanding the grating price per m² involves considering material types, structural requirements, manufacturing processes, and reliable suppliers. Armed with comprehensive insights, consumers and decision-makers can make informed choices that balance cost-effectiveness with superior performance, ensuring long-term success and safety in grating applications.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

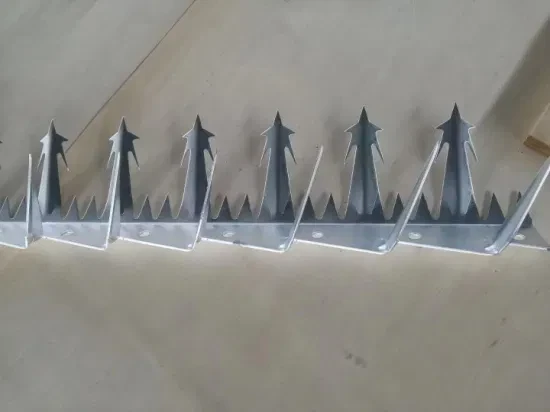

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA