Jan . 21, 2025 04:38 Back to list

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Beyond intrinsic material and manufacturing costs, external economic factors also play a crucial role. Global supply chain dynamics, including raw material availability and transportation costs, have a direct impact on pricing. Staying informed on these market trends can offer businesses strategic advantages, allowing procurement at more favorable times. Supplier Expertise and Its Role The expertise and reliability of the supplier significantly influence product quality and price. Partnering with established manufacturers known for stringent quality controls ensures a trustworthy product. These suppliers often provide detailed product information, including load charts and compliance with industry standards, assisting in more informed purchasing decisions that align with project specifications and budget constraints. Innovative Solutions for Cost-Effective Designs Exploring innovative design and installation approaches may offer additional cost benefits. Incorporating modular and prefabricated sections, for instance, can streamline installation processes while reducing labor costs. Many leading suppliers provide design assistance and tools, ensuring optimized grating specifications that meet both structural requirements and budgetary limits. Environmental Considerations and Regulations Sustainability and compliance with environmental regulations increasingly influence commercial decisions. Many enterprises opt for eco-friendly materials and processes, potentially qualifying for tax incentives or extended lifecycle benefits, balancing initial higher material costs with longer-term savings. Conclusion Bar grating pricing is a multifaceted issue that requires a thoughtful approach, balancing material choice, manufacturing processes, and customization needs against economic conditions and supplier expertise. By considering all these factors, businesses can navigate the intricacies of this essential construction element effectively. Knowledge is power; arming procurement teams with the right information facilitates smart purchasing choices, setting the foundation for successful projects that meet both immediate and future goals.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

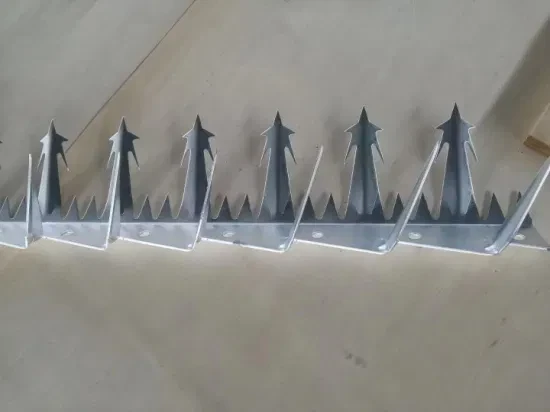

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA