Jan . 25, 2025 05:16 Back to list

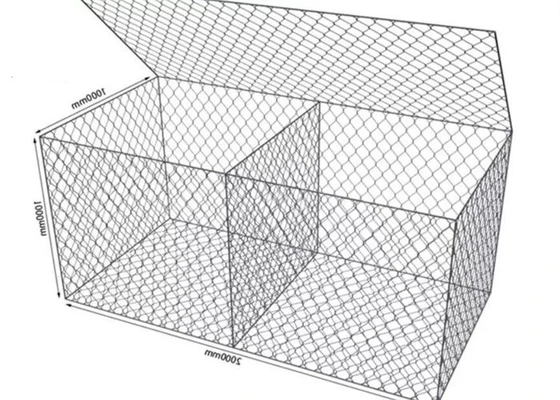

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Building trust and credibility in grating platform design also involves transparency and testing. Reputable manufacturers and designers will offer extensive testing data and certifications that verify adherence to international standards, such as ISO or ASTM. Such certifications assure clients of the platform’s quality and compliance with global best practices, cementing trustworthiness in the design. Professional installation is another critical factor that influences the success and safety of grating platforms. Incorrect installation can undermine even the best-designed platform, leading to potential hazards and increased liability. Therefore, engaging experienced installers who follow manufacturer guidelines and industry standards is essential to maintain the platform's integrity and functionality. Designers and manufacturers must remain abreast of technological advancements and industry trends to offer cutting-edge solutions. Innovations in materials science, such as the development of more durable composites, and advancements in CAD software for design precision, continue to elevate grating platform capabilities. These technological integrations not only enhance the performance and lifespan of the platforms but also streamline the design process, resulting in more cost-effective and timely project completions. Building authority in grating platform design fundamentally relies on an organization's experience, adaptability, and commitment to quality. A history of past projects successfully implemented across diverse environments and challenging scenarios speaks volumes about the expertise of a design team. Testimonials and case studies from satisfied clients across multiple industry sectors further bolster an organization’s authoritative stand in the market. Ultimately, a grating platform's design represents the convergence of reliability, aesthetics, and innovation. By ensuring that every aspect of the design meets the required specifications and industry standards, while also accommodating for future needs through scalable and flexible design choices, engineers and designers can provide platforms that are not only fit for purpose today but are also adaptable to the changes of tomorrow.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA