Feb . 06, 2025 03:09 Back to list

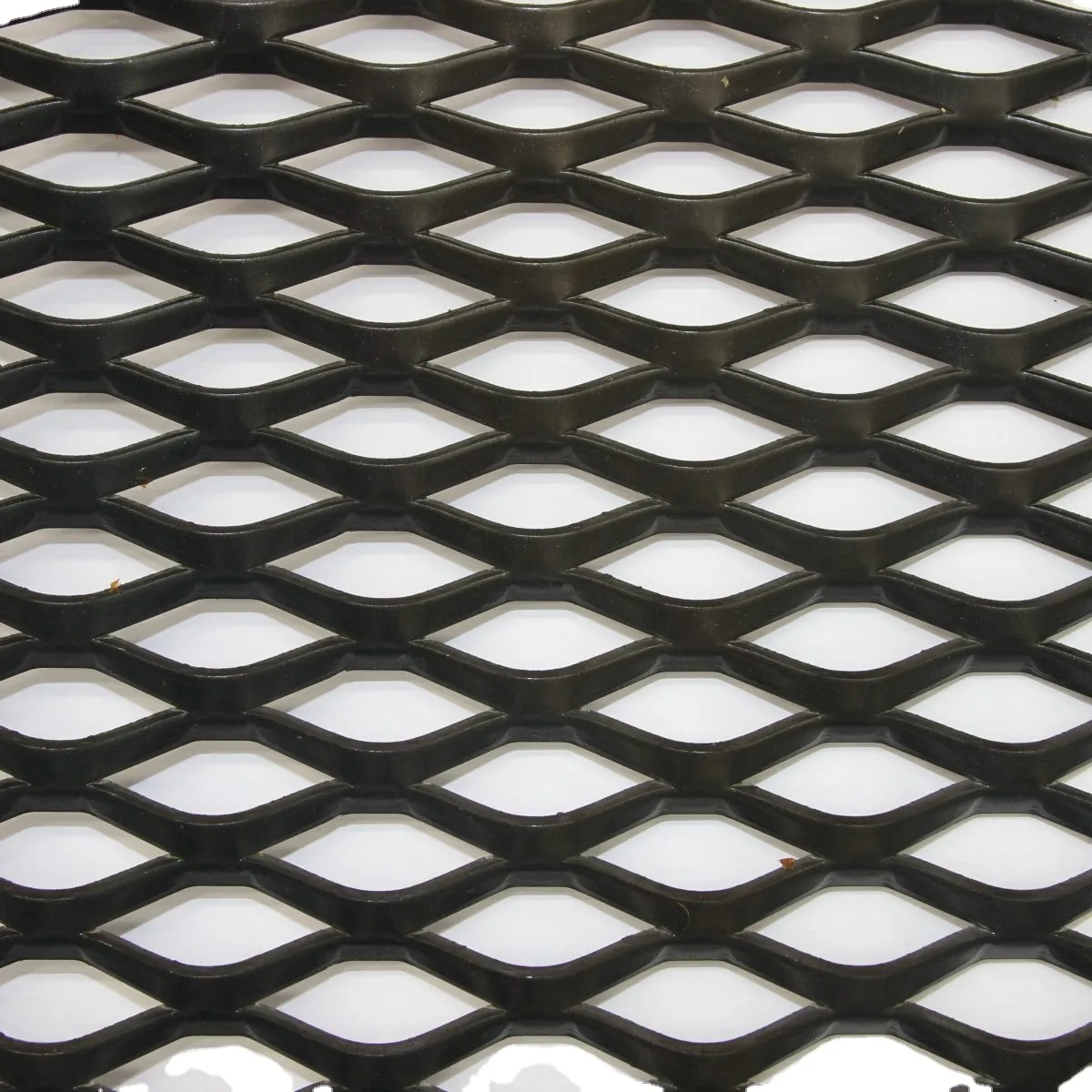

galvanized grating

Trustworthiness in material specifications is vital for decision-makers in construction and industry. Consistent quality control during the manufacturing process of hot dip galvanized grating assures reliable performance. Manufacturers who adhere strictly to galvanized standards produce products that consistently meet the demands of their intended applications. Customers can thus trust the integrity of the material, knowing it has been subjected to rigorous testing and quality checks. Moreover, sustainable manufacturing practices have increasingly become a focal point within the industry. Hot dip galvanized grating stands out not only for its structural and protective properties but also for its environmental considerations. The galvanizing process is conducive to recycling, with both the steel and zinc materials being fully recyclable, supporting longer-term sustainability goals. In conclusion, grating hot dip galvanized products exemplify superior industrial and architectural material choice through their durability, adherence to rigorous standards, and sustainable lifecycle. This makes them a favored choice for professionals seeking reliable performance in demanding climates. Whether utilized in heavy industrial applications, pedestrian walkways, or architectural features, these gratings offer a blend of functionality, safety, and economic efficiency unmatched by alternatives. Their proven track record assures that as industries evolve, these materials will continue to provide critical support, affirming their place as a staple in future infrastructure development. For businesses and engineers exploring cutting-edge infrastructure options, grating hot dip galvanized solutions represent a smart investment. By leveraging the expertise in this field, stakeholders can ensure that their projects benefit from the strength, longevity, and sustainability that characterize these materials, powered by a commitment to excellence and strategic foresight.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA