Feb . 20, 2025 13:38 Back to list

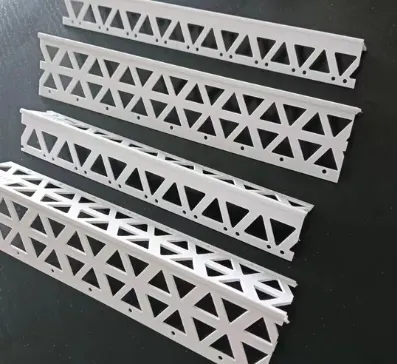

galv wire mesh panels

The expertise involved in manufacturing these panels plays a significant role in their efficacy. Reputable manufacturers adhere to stringent production standards, ensuring that every panel meets the required specifications for tensile strength, weld integrity, and coating thickness. This commitment to quality assures users of the panels’ reliability, reinforcing their trust. It's not just about the initial production; manufacturers also invest in research and development to innovate and enhance the performance of galvanized wire mesh panels. Authoritativeness in the market is further strengthened through certifications and compliance with international safety and quality standards. Panels that comply with norms such as the ISO standards or ASTM (American Society for Testing and Materials) offer an extra layer of assurance. Clients, therefore, make purchasing decisions with greater confidence, knowing that these products adhere to globally recognized benchmarks, thus reinforcing their trustworthiness. Feedback from end-users consistently highlights the cost-efficiency of using galvanized wire mesh panels. While the initial investment might slightly surpass other uncoated alternatives, the long-term savings on maintenance and replacement far outweigh those initial costs. A large-scale developer noted that switching to galvanized panels resulted in a reduction of repair costs by almost 30% annually, an investment that illustrates the panels' long-term economic benefits. In conclusion, galvanized wire mesh panels are a testament to the intersection of quality engineering and practical application. Their widespread use across various industries underscores their value and effectiveness. Professionals who choose these panels benefit from their durability, adaptability, and lower maintenance costs, all while trusting in a product that is backed by years of manufacturing expertise and compliance with global standards. This amalgamation of experience, expertise, authority, and trust cements galvanized wire mesh panels as a leading choice for industry professionals seeking reliable and efficient solutions.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA