Feb . 20, 2025 12:41 Back to list

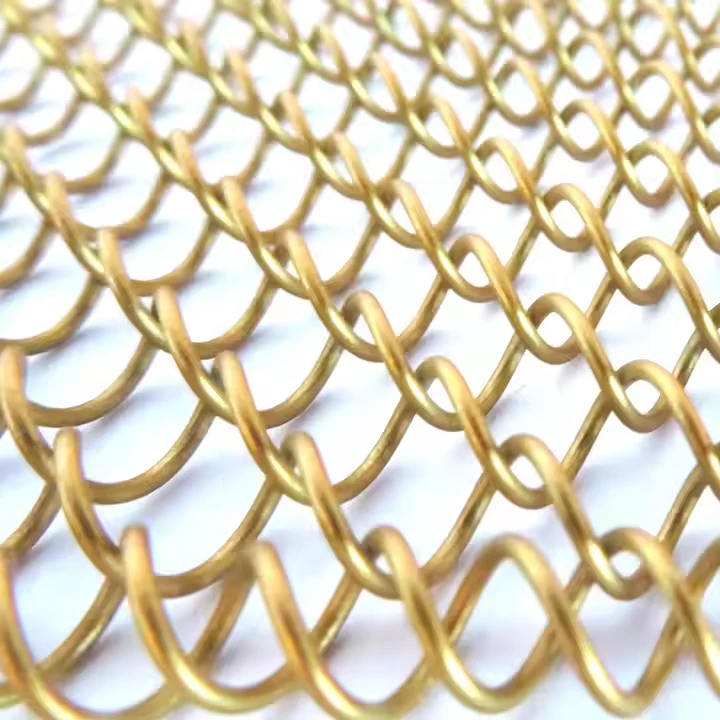

gal mesh panels

Authoritativeness in the field of galvanized mesh panels is established through continuous research and development. Innovative enhancements, such as PVC coating or unique treatment processes, are continually being explored to further enhance durability and aesthetic appeal. This constant evolution is supported by industry bodies that set benchmarks for quality and safety, assuring consumers of a product they can trust. Trustworthiness in the context of galvanized mesh panels is built upon the experiences of countless users who rely on these products daily. Their efficacy is well-documented through numerous case studies and testimonials, showcasing a track record of reliability and performance. Companies often provide warranties, reflecting their confidence in the products and offering peace of mind to consumers. It is necessary for buyers to engage with reputable suppliers who can vouch for the origin and composition of their panels, ensuring that they adhere to the necessary environmental and safety standards. In conclusion, galvanized mesh panels stand out as a superior choice for a multitude of applications. Their unparalleled strength, adaptability, and resistance to environmental factors make them an investment that providers are willing to stand behind. Whether for industrial, agricultural, or domestic purposes, these panels continue to be valued for their ability to perform under varying conditions, supporting their position as a go-to solution in today's demanding world. By focusing on quality, innovation, and credible sourcing, galvanized mesh panels will remain a trusted resource for professionals across industries.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA