Jan . 20, 2025 01:11 Back to list

galvanized grating

Authoritative industry reports emphasize the cost-effectiveness of floor mesh grating. When analyzed over time, the initial investment in mesh grating proves economical due to its long service life and minimal maintenance requirements. The ease of installation and the reduced need for expensive repairs or replacements contribute to the overall savings, making it an attractive option for budget-conscious project managers and engineers. In terms of trustworthiness, real-life case studies provide compelling evidence of mesh grating's efficacy. For instance, in the oil and gas sector, mesh grating is extensively used on offshore rigs where its non-slip surface and corrosion resistance are indispensable. Similarly, in urban infrastructure, it is used in pedestrian bridges and railway platforms, underlining its reliability and safety for public usage. Considering environmental factors, eco-conscious developers can take comfort in knowing that many mesh grating products are produced with sustainability in mind. Manufacturers increasingly utilize recycled materials and environmentally friendly production processes, aligning with global efforts to reduce carbon footprints. Hence, selecting floor mesh grating not only supports structural integrity and safety but also contributes to sustainable building practices. In conclusion, floor mesh grating stands out as a superior choice for a multitude of applications, from heavy-duty industrial settings to innovative architectural projects. Its proven strength, safety benefits, and adaptability make it a trusted component in modern construction. Both cost-effective and environmentally sustainable, floor mesh grating is positioned to remain a staple in material selection for years to come, underscoring its ongoing relevance and indispensability in the field.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

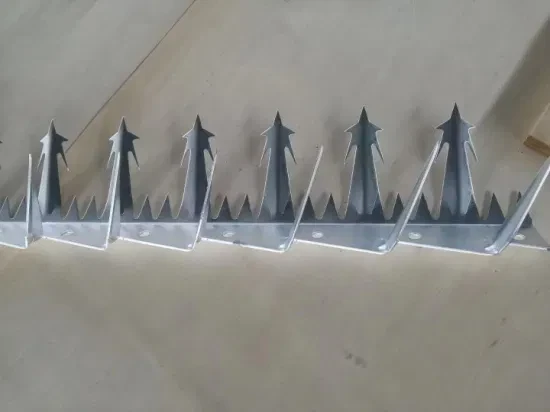

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA