Jan . 14, 2025 15:37 Back to list

Fiberglass Fabric 200g~1200g E-Glass Woven Roving Industrial Fiberglass Mesh

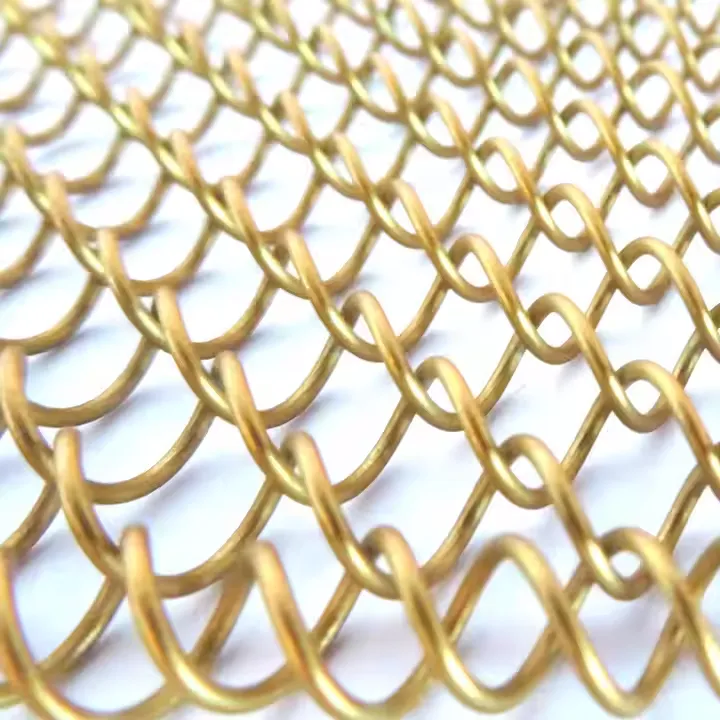

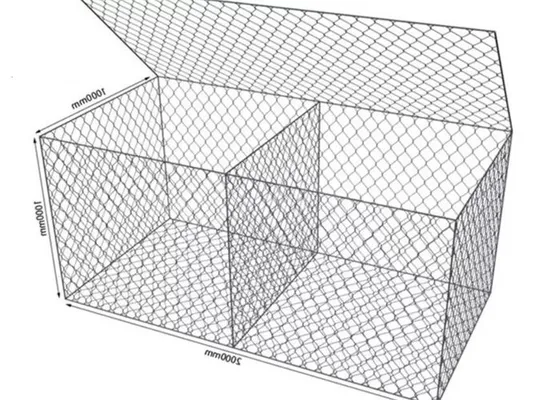

On the topic of trustworthiness, it is essential to take into account the testimonials and case studies available from seasoned industry players who have utilized these grids in their projects. For example, an architectural firm responsible for the renovation of a historical site shared that the use of custom-cut brass floor grid meshes allowed them to maintain the aesthetic integrity of the venue while ensuring the structural upgrades required for modern safety standards. Such real-world experiences underline the importance of choosing floor grid meshes tailored to specific needs and environments. Floor grid meshes are not just a product but a critical component in countless fields, from constructing awe-inspiring architectural wonders to ensuring the smooth operation of industrial powerhouses. Their versatility and adaptability make them indispensable in overcoming the unique challenges posed by various applications. Those who grasp the true potential of floor grid meshes are empowered to select solutions that not only meet but exceed their project requirements — ensuring safety, enhancing durability, and providing peace of mind. Through a comprehensive understanding of materials, standards, and real-world application scenarios, professionals can demonstrate an unparalleled level of expertise and authoritativeness. The trust placed in these products is reflected in their widespread application across diverse sectors, reinforcing their status as a cornerstone in modern architectural and industrial design. As the landscape of construction and design continues to evolve, the role of floor grid meshes will undoubtedly expand, solidifying their position as an integral element in the infrastructure of tomorrow.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA