Sep . 01, 2025 14:11 Back to list

Aluminum Grating Installation Guide

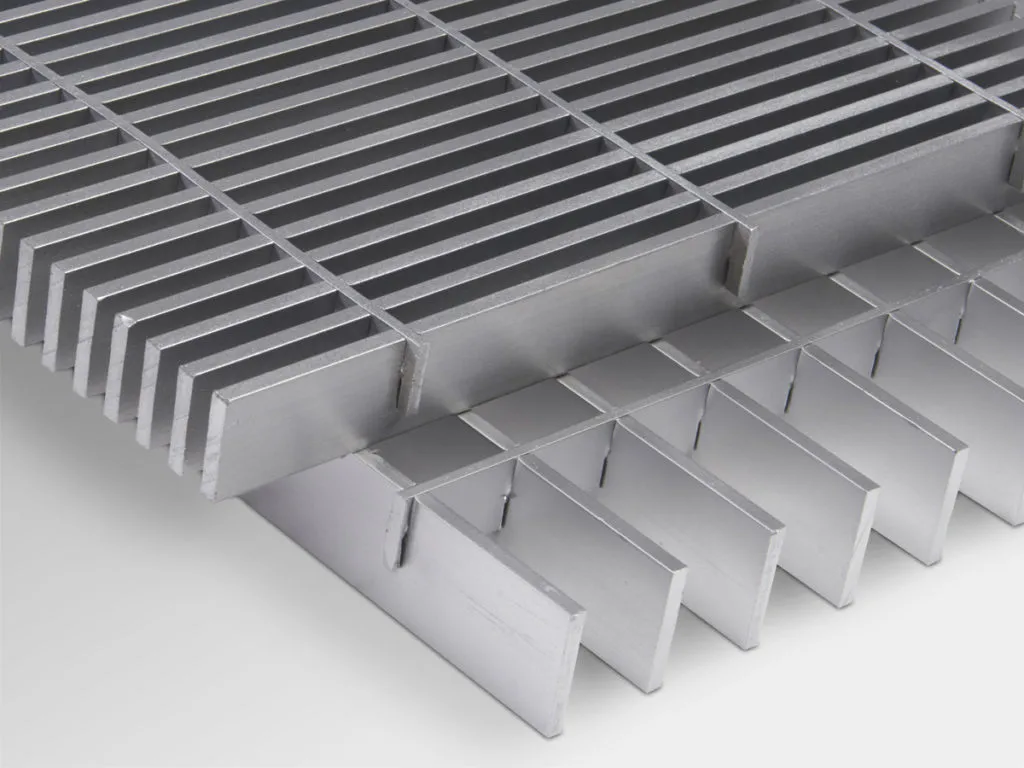

Aluminum grating has become an increasingly popular choice for industrial, commercial, and architectural applications due to its exceptional strength-to-weight ratio and corrosion resistance. Known interchangeably as aluminum walkway grating in many international markets, this versatile material offers distinct advantages over traditional steel alternatives, particularly in environments where weight reduction or rust prevention are priorities. The installation of aluminum bar grating requires specific techniques to maximize its performance characteristics while ensuring long-term durability and safety.

Unlike conventional steel grating, aluminum grating presents unique installation considerations stemming from its material properties. The lower density of aluminum affects everything from handling procedures to fastening methods, while its thermal expansion characteristics demand particular attention in outdoor applications. Aluminum walkway grating installations must account for these factors to prevent common issues like warping, loosening, or galvanic corrosion when connecting to dissimilar metals.This comprehensive guide covers all aspects of aluminum bar grating installation, from pre-installation planning to final inspection.

Pre-Installation Planning for Aluminum Grating

Successful aluminum grating installation begins with thorough planning and preparation long before the first panel is put in place. The lightweight nature of aluminium grating makes it easier to handle than steel alternatives, but this same characteristic requires careful consideration of support spacing and load distribution to prevent excessive deflection under weight.

Key planning steps for aluminum bar grating installations include:

Structural Assessment

Verify support frame integrity and alignment

Check for proper clearance between supports

Confirm load-bearing capacity matches design requirements

Material Verification

Inspect grating for shipping damage

Check panel sizes against installation drawings

Verify alloy type and surface treatment

Environmental Considerations

Account for thermal expansion in outdoor installations

Plan for drainage in wet environments

Consider chemical exposure in industrial settings

For aluminum walkway grating used in corrosive environments, additional precautions include:

Isolation of aluminum from dissimilar metals

Selection of compatible fasteners

Protection of cut edges

Planning for future inspection access

Proper planning also involves gathering the right tools for aluminum bar grating installation, which typically includes:

Non-marring rubber mallets

Aluminum-specific cutting blades

Corrosion-resistant fasteners

Protective coatings for cut edges

Specialized lifting equipment for large panels

Installation Techniques for Aluminum Bar Grating

The actual installation process for aluminum bar grating requires attention to detail to ensure proper alignment, secure fastening, and long-term performance. Unlike steel grating, aluminium grating demands specific handling techniques to prevent surface damage and maintain its corrosion-resistant properties.

Step-by-step installation guidelines:

Panel Placement

Use soft slings for lifting to prevent surface scratches

Align bearing bars with primary support structure

Maintain equal spacing between panels

Temporary Fixing

Secure panels with clamps before permanent fastening

Check for proper fit and alignment

Verify slip resistance direction if applicable

Permanent Fastening

Pre-drill holes to prevent material distortion

Follow torque specifications to avoid over-tightening

Special considerations for aluminum grating in different applications:

Industrial Platforms: Focus on load distribution and anti-slip orientation

Pedestrian Walkways: Emphasize smooth edges and surface finish

Marine Applications: Prioritize galvanic isolation and drainage

Architectural Features: Maintain aesthetic alignment and clean lines

For aluminium grating installations requiring field modifications:

Use carbide-tipped blades for clean cuts

Deburr all cut edges thoroughly

Apply touch-up coating to exposed aluminum

Never weld without proper aluminum welding expertise

Aluminum walkway grating:Surface Protection and Touches

After installing aluminum walkway grating, proper finishing techniques ensure long-term performance and maintain the material's inherent corrosion resistance. Unlike steel alternatives that might rely on thick protective coatings, aluminum walkway grating typically uses its natural oxide layer for protection, making proper edge treatment especially important.

Special considerations for aluminum walkway grating in harsh environments:

Apply clear coat protection in coastal areas

Use non-abrasive cleaning methods

Implement regular protective coating renewal

Inspect for galvanic corrosion points

FAQs About Aluminum Grating

What makes aluminum grating installation different from steel grating?

The installation of aluminum grating differs from steel in several key aspects. The lower weight requires different handling techniques but allows for wider support spacing. Aluminium grating cannot be welded like steel without special equipment and expertise, necessitating mechanical fastening systems. Thermal expansion rates are higher with aluminum, demanding proper accommodation in the installation design. Additionally, aluminum bar grating requires isolation from dissimilar metals to prevent galvanic corrosion, a concern not present with homogeneous steel systems.

How do you prevent corrosion when installing aluminum grating?

Preventing corrosion in aluminum grating installations involves multiple protective measures. Always use stainless steel or aluminum fasteners to avoid galvanic reactions. Apply touch-up coatings to any field-cut edges immediately after cutting. Install isolation pads where the aluminium grating contacts other metals. Ensure proper drainage to prevent water pooling. For harsh environments, specify anodized or painted aluminum bar grating products and maintain the protective finishes regularly.

What spacing should be used for supports under aluminum grating?

Support spacing for aluminum grating depends on the specific alloy, bar configuration, and expected loads. Typical spacing ranges from 24 inches for light pedestrian traffic to 12 inches for heavy industrial loads. Always consult the manufacturer's load tables for the particular aluminium grating product being installed. Remember that aluminum bar grating can span further than steel at equivalent weights, but deflection limits rather than strength often govern spacing requirements.

Can aluminum grating be modified on-site during installation?

Aluminum grating can be field-modified with proper techniques. Use carbide-tipped blades for clean cuts and deburr all edges thoroughly. Never use torches or plasma cutters, as these damage the material's heat treatment. For aluminium grating, mark cuts carefully as mistakes are harder to correct than with steel. Always wear proper PPE when cutting or drilling aluminum bar grating, as the chips can be sharp and the dust requires respiratory protection.

How do you account for thermal expansion in aluminum grating installations?

Accommodating thermal expansion is critical for aluminum grating, which expands nearly twice as much as steel per degree of temperature change. Use slotted holes in clips or brackets to allow movement. Increase panel spacing gaps in hot environments. Orient fasteners to permit sliding where possible. For long runs of aluminium grating, include expansion joints at appropriate intervals. With aluminum bar grating systems, remember that dark colors absorb more heat and thus experience greater expansion than light-colored surfaces.

Proper installation of aluminum grating requires understanding the unique characteristics of this lightweight but durable material. From careful handling to prevent surface damage to the selection of appropriate fastening systems, each step in the aluminium grating installation process contributes to the long-term performance and safety of the completed assembly. By following manufacturer guidelines and industry best practices, installers can ensure that aluminum bar grating systems deliver their full potential of corrosion resistance, strength, and aesthetic appeal.

Remember that the initial quality of installation directly impacts the lifecycle cost and maintenance requirements of aluminum walkway grating systems.Come and consult us quickly.

Latest News

-

Heavy Duty Yard Gully - Durable Industrial Drainage Solutions for Harsh Environments

NewsNov.24,2025

-

Everything You Need to Know About In Grating: Applications, Benefits & Trends

NewsNov.24,2025

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA