Nov . 17, 2025 17:01 Back to list

Wire Mesh Conveyor Belts - Stainless Steel, Heat-Resistant

Wire Mesh Conveyor Belts is a key solution in the General equipment manufacturing industry, specifically within Manufacturing of conveying machinery and Conveyor belt manufacturing. This article explores how SHIJIAZHUANG CHENGSEN TRADING CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Wire Mesh Conveyor Belts Overview

- Benefits & Use Cases of Wire Mesh Conveyor Belts in Conveyor belt manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on Wire Mesh Conveyor Belts from SHIJIAZHUANG CHENGSEN TRADING CO., LTD.

Wire Mesh Conveyor Belts Overview

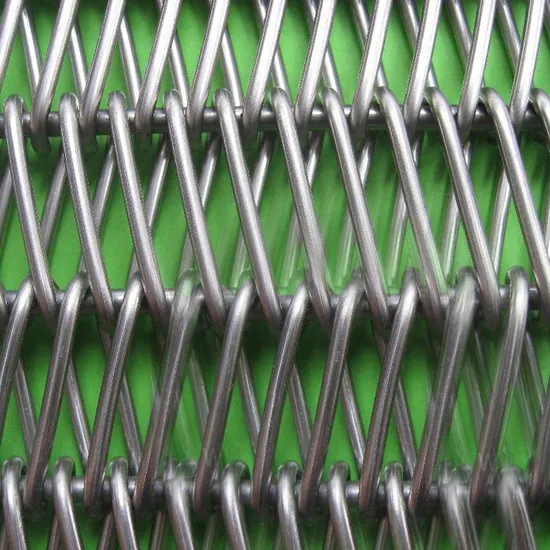

Wire mesh belts are engineered, open-area conveyor media made from interlaced metal wires that form a durable, heat- and corrosion-resistant pathway for product transport. In the conveyor belt manufacturing value chain, they serve as the trusted choice for processes that require airflow, drainage, or rapid heat transfer—such as baking, drying, heat treatment, quenching, and cooling. SHIJIAZHUANG CHENGSEN TRADING CO., LTD. manufactures mesh conveyor belt solutions in 201, 304, 316L, and 310S stainless steel to match application demands from general-purpose conveying to aggressive chemical or high-temperature environments. Typical specifications include custom widths and lengths, wire diameters, pitches, edge finishes (welded, looped, or chain edges), and drive interfaces (sprocket- or friction-driven). Popular constructions include balanced weave, compound weave, flat-flex/ladder, and eye-link designs, each optimized for tracking stability and load distribution. For B2B decision makers seeking predictable performance, Chengsen’s stainless steel wire mesh conveyor belt options deliver dimensional accuracy, consistent open area, and repeatable tension characteristics, enabling seamless integration into OEM machines and retrofit projects across food, metallurgy, glass, and electronics processing lines.

Benefits & Use Cases of Wire Mesh Conveyor Belts in Conveyor belt manufacturing

OEMs and system integrators rely on wire conveyor belt designs when they need precise product support with controlled airflow and minimal surface contact. Typical use cases include tunnel ovens and dryers, freezer in-feeds, oil or water quench tanks, powder coating cure lines, glass annealing, sintering, and parts washing. Compared with solid belts, mesh designs reduce carryback, speed up cleaning, and improve heat transfer, lowering energy use and cycle times. SHIJIAZHUANG CHENGSEN TRADING CO., LTD. supplies a wide range of mesh types and alloys—201 and 304 for cost-effective general duty, 316L for superior corrosion resistance, and 310S for high-temperature stability—so engineers can tune performance to process conditions. Competitive advantages include excellent flatness, accurate pitch control for smooth sprocket engagement, robust edge treatments to resist racking, and consistent open-area percentages that drive predictable throughput. Whether you need lightweight flat-flex for delicate food products or heavy-duty balanced weave for metal components, Chengsen’s wire mesh belts are built to specification for precise tracking, long life, and easy integration into new or existing conveyor frames.

Cost, Maintenance & User Experience

Total cost of ownership for Wire Mesh Conveyor Belts is driven by service life, uptime, sanitation requirements, and energy consumption. Stainless steel constructions resist wear and thermal fatigue, which extends belt life and reduces unplanned stoppages. Open-area designs lower cleaning time and chemical usage while improving drainage and heat transfer—benefits that translate into higher line availability and faster changeovers. Maintenance best practices include routine inspection for tension and alignment, periodic verification of sprocket engagement, timely replacement of worn edge loops or connecting rods, and keeping spare splice sections on hand for rapid swaps. Customers in the manufacturing of conveying machinery sector report stable tracking, minimal stretch after initial run-in, and easier sanitation compared with closed-surface alternatives. SHIJIAZHUANG CHENGSEN TRADING CO., LTD. supports users with application guidance, recommended material selections (201/304/316L/310S), and tailored specifications that help maximize ROI over the belt’s lifecycle. For many lines, the efficiency gains and reduced downtime achieved with a well-specified mesh conveyor belt offset initial investment quickly.

Sustainability & Market Trends in General equipment manufacturing industry

Sustainability priorities—energy efficiency, water reduction, and material circularity—are reshaping conveyor design. Wire mesh belts inherently support these goals: open structures enable faster drying and heating with less fan power, reduce water carryover in washers, and lower cleaning chemical usage. Stainless steel is widely recyclable, and selecting the right alloy (304 for general corrosion, 316L for aggressive environments, 310S for high heat) can extend service life, reducing material turnover. Market trends include higher automation, tighter temperature control, and more data-driven maintenance. Mesh conveyors are increasingly paired with sensors for load, temperature, and vibration monitoring to predict wear and optimize cleaning cycles. SHIJIAZHUANG CHENGSEN TRADING CO., LTD. aligns with these trends through precise manufacturing controls, material traceability, and engineering support that helps users specify the most efficient mesh type and open area for their process. The result: lower resource consumption per unit produced and measurable contributions to corporate sustainability targets—without compromising throughput or product quality.

Conclusion on Wire Mesh Conveyor Belts from SHIJIAZHUANG CHENGSEN TRADING CO., LTD.

From ovens and dryers to washers and coolers, Wire Mesh Conveyor Belts deliver the airflow, stability, and cleanliness modern production demands. As a trusted supplier in the conveyor belt manufacturing segment, SHIJIAZHUANG CHENGSEN TRADING CO., LTD. provides wire mesh belts, mesh conveyor belt designs, and stainless steel wire mesh conveyor belt solutions tailored to exact process needs—helping B2B leaders improve uptime, energy efficiency, and product consistency. Contact us: email: metals@chengsenchina.com. Visit our website: https://www.chengsenmesh.com

Latest News

-

Electro and Hot-Dip Galvanized Welded Wire Mesh Roll 1/8–4”

NewsNov.17,2025

-

Durable Circular Grating Solutions for Industrial Applications

NewsNov.17,2025

-

2m x 1m x 0.5m Galfan Gabion Basket Retaining Wall Design

NewsNov.17,2025

-

Ferrotech Grating: Durable Solutions for Modern Industry

NewsNov.17,2025

-

Trusted Aluminum Grating Manufacturers | Durable & Light

NewsNov.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA