Sep . 01, 2025 06:00 Back to list

Customized Irregular Steel Grating for Industrial Platforms

Introduction to Advanced Industrial Grating Solutions

In the rapidly evolving industrial landscape, the demand for robust, adaptable, and high-performance infrastructure components is paramount. This is particularly true for elevated platforms, walkways, and mezzanines, where safety, durability, and customization are non-negotiable. Traditional grating solutions often fall short in accommodating complex architectural designs or specific operational requirements. This article delves into the transformative capabilities of Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating, a solution engineered to address these challenges with precision and innovation. We will explore its manufacturing intricacies, technical superiority, diverse applications, and the tangible benefits it offers to modern industrial operations.

Current Industry Trends and Market Demands

The industrial sector is witnessing several key trends that underscore the importance of specialized grating solutions. Digitalization and Industry 4.0 initiatives are driving the need for smarter, more efficient factory layouts, often requiring platforms that integrate seamlessly with automated systems and robotics. Furthermore, stringent safety regulations and an increased focus on worker ergonomics necessitate flooring solutions that provide superior slip resistance, structural integrity, and ease of maintenance. Environmental considerations are also pushing for materials with extended service life and reduced lifecycle impact. This convergence of factors amplifies the demand for a Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating that can offer bespoke configurations and advanced material properties.

- Increased complexity in facility design, demanding non-standard platform shapes.

- Emphasis on worker safety, driving demand for high load capacity and anti-slip surfaces.

- Longer expected service life for industrial infrastructure to reduce operational expenditures.

- Requirement for corrosion-resistant materials in harsh operating environments.

Manufacturing Process Flow: From Raw Material to Precision Grating

The creation of a Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating involves a meticulous multi-stage process, ensuring structural integrity, precise dimensions, and superior surface finish. Our commitment to quality begins with material selection and extends through advanced fabrication techniques to rigorous final inspection.

1. Material Selection & Preparation

We utilize high-grade structural steels such as ASTM A36, Q235, or stainless steel grades like 304 or 316, depending on the application's corrosion resistance and strength requirements. Materials undergo initial quality checks for chemical composition and mechanical properties.

- Material: Carbon Steel (e.g., Q235B, A36), Stainless Steel (e.g., 304, 316L), Aluminum Alloy.

- Properties: High tensile strength, excellent corrosion resistance (for SS), good weldability.

2. Precision Cutting & Shaping

Utilizing advanced CNC plasma or laser cutting technologies, raw steel plates are precisely cut into the irregular, special shapes required for the platform. This stage ensures high dimensional accuracy and minimizes material waste.

3. Grating Fabrication (Bearing Bar & Cross Bar Assembly)

The bearing bars, which carry the primary load, are then notched or punched. Cross bars are inserted and joined through various methods:

- Pressure Welding: This fully automated process fuses bearing bars and twisted square cross bars under high heat and pressure, creating a strong, monolithic panel.

- Swage Locked: Bearing bars are notched, and square cross bars are inserted and cold-pressed into place for a secure mechanical lock.

- Welded Grating: Individual components are precision-welded together.

4. Secondary Fabrication & Finishing

This stage involves cutting openings, nosings, toe plates, and installing specialized clips or banding as per design. All edges are carefully finished to remove burrs. For enhanced corrosion resistance and aesthetics, the gratings undergo surface treatments.

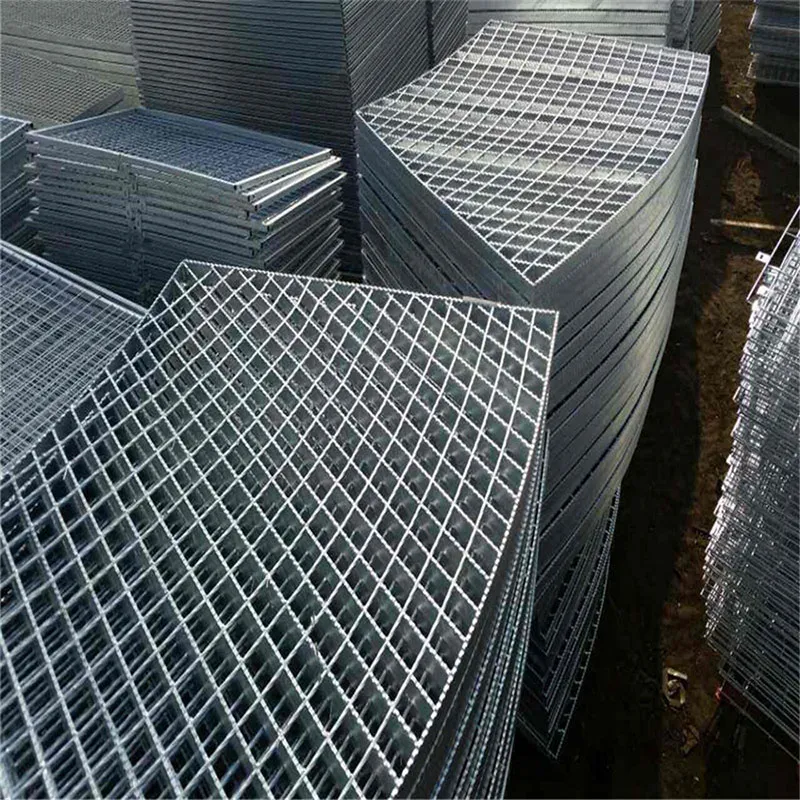

- Hot-dip Galvanization: Conforming to ISO 1461/ASTM A123 standards, providing excellent long-term corrosion protection.

- Painting/Powder Coating: For specific aesthetic or additional protective requirements.

- Electropolishing (for Stainless Steel): Enhances corrosion resistance and provides a mirror-like finish.

5. Quality Control & Testing

Each Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating panel undergoes stringent quality checks:

- Dimensional Accuracy: Verified against engineering drawings.

- Load Bearing Capacity: Sample testing according to ANSI/NAAMM MBG 531 standards.

- Weld Integrity: Visual inspection and non-destructive testing (NDT) if required.

- Surface Finish: Adherence to galvanization thickness or coating specifications.

Technical Specifications and Performance Metrics

Understanding the technical parameters of Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating is crucial for ensuring optimal performance and safety in diverse industrial environments. Our products are designed and manufactured to meet or exceed international standards.

Key Technical Parameters

| Parameter | Specification Range | Relevant Standards |

|---|---|---|

| Bearing Bar Dimensions | Thickness: 3mm - 10mm; Depth: 25mm - 100mm | ANSI/NAAMM MBG 531, AS1657 |

| Bearing Bar Pitch | 15mm, 20mm, 25mm, 30mm, 34mm, 40mm, 60mm | YBT 4001.1-2007, BS 4592 |

| Cross Bar Pitch | 50mm, 100mm (standard), customizable | YBT 4001.1-2007, BS 4592 |

| Material Grade | Q235B, A36, SS304, SS316, 6063 Aluminum | ASTM A36, ASTM A240, GB/T 700 |

| Surface Treatment | Hot-dip Galvanized, Painted, Powder Coated, Mill Finish | ISO 1461, ASTM A123 |

| Load Capacity | Up to 200 kN/m² (specific to design) | FEA Verified, EN ISO 14122-2 |

| Service Life (Galvanized Carbon Steel) | 25+ years in typical industrial environments | ISO 9223 (Corrosion categories) |

Our engineering team employs advanced Finite Element Analysis (FEA) software to simulate load distribution and deflection, ensuring that each customized design meets the required safety factors and performance benchmarks under specific operational loads and environmental conditions.

Diverse Application Scenarios and Key Advantages

The adaptability of a Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating makes it indispensable across a multitude of heavy industries. Its design flexibility allows it to conform to complex footprints, circumvent obstacles, and integrate seamlessly into existing structures.

Target Industries & Typical Use Cases:

- Petrochemical & Oil & Gas: Offshore platforms, refinery walkways, drilling rig flooring. Advantage: Superior corrosion resistance (especially SS316), excellent drainage, anti-slip properties crucial in hazardous environments.

- Metallurgy & Mining: Smelter platforms, conveyor walkways, processing plant mezzanines. Advantage: High load bearing capacity, resistance to abrasive wear, robust structural integrity for heavy equipment support.

- Power Generation (Thermal, Hydro, Nuclear): Boiler platforms, turbine hall walkways, cable trenches covers. Advantage: Heat resistance, excellent ventilation (energy saving by reducing heat build-up), robust under high-temperature fluctuations.

- Water Supply & Drainage: Wastewater treatment plant catwalks, pump station platforms, trench covers. Advantage: Exceptional corrosion resistance in humid, chemical-rich environments, easy to clean, promotes efficient drainage.

- Chemical Processing: Tank access platforms, mixing areas, production line walkways. Advantage: Resistance to chemical attack (with appropriate material and coating), fire resistance, safety grating options.

- Food & Beverage: Processing floors, cleanroom platforms. Advantage: Hygienic stainless steel options, easy to sanitize, compliance with food safety regulations.

Technical Advantages of Our Custom Grating Solutions

The inherent advantages of our Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating stem from a combination of superior material science, advanced manufacturing techniques, and a deep understanding of industrial demands.

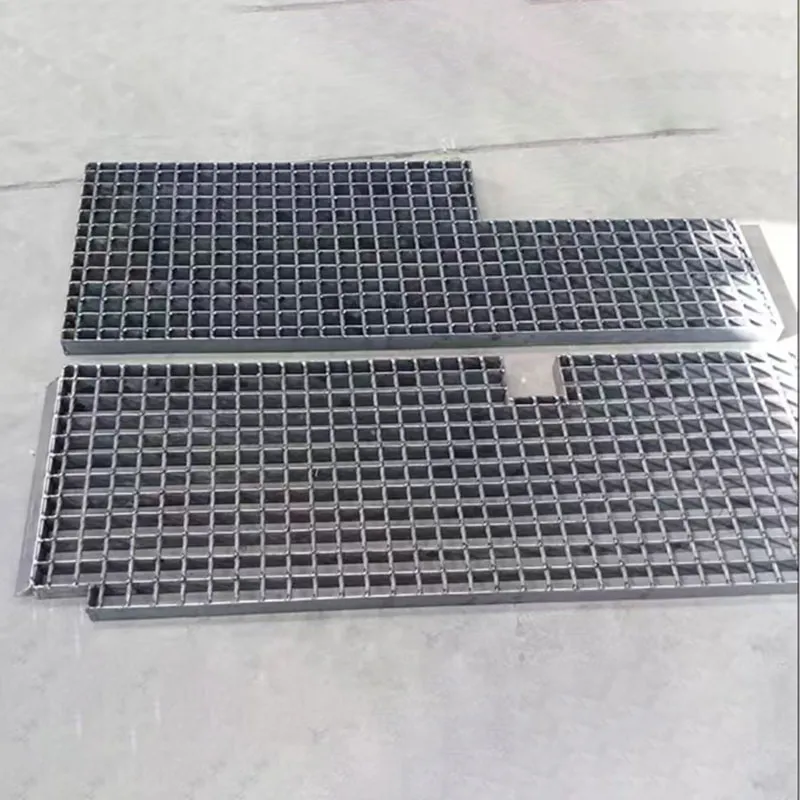

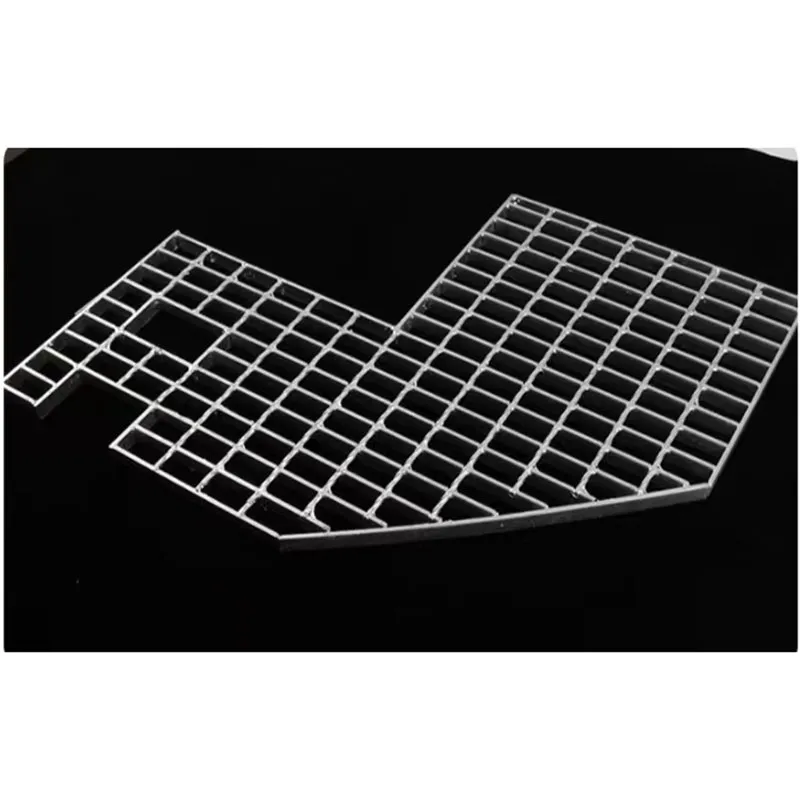

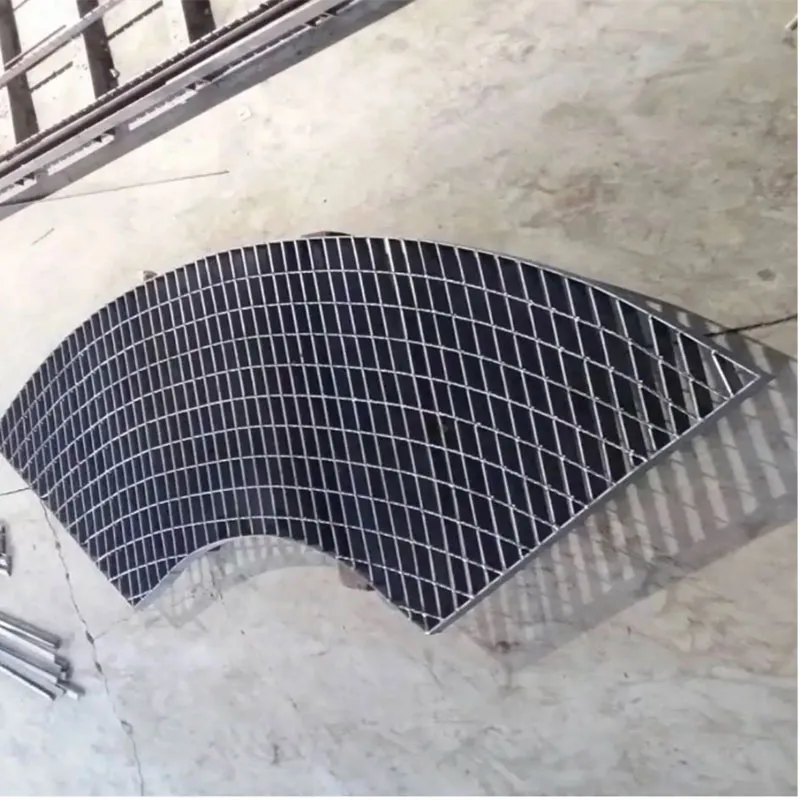

- Unparalleled Customization: Capable of fabricating complex geometries, angles, curves, and cut-outs to fit any architectural or operational requirement. This significantly reduces on-site modification costs and installation time.

- High Strength-to-Weight Ratio: Engineered for maximum load-bearing capacity with optimized material usage, leading to lighter structures without compromising safety or durability. This translates to lower structural support costs.

- Exceptional Durability & Longevity: With robust materials and corrosion-resistant finishes like hot-dip galvanization (minimum 610 g/m² zinc coating as per ISO 1461), our gratings are designed for extended service life, minimizing replacement and maintenance cycles.

- Enhanced Safety Features: Options for serrated bearing bars provide superior slip resistance, even in wet or oily conditions. Compliance with OSHA and local safety codes ensures a safer working environment.

- Optimal Drainage & Ventilation: Open mesh design facilitates efficient drainage of liquids and debris, preventing accumulation. It also allows for excellent airflow, which is critical in environments requiring heat dissipation or fume extraction (e.g., energy saving in ventilation).

- Ease of Installation & Maintenance: Prefabricated sections with precise dimensions and integrated fixing mechanisms simplify installation. The open design also makes cleaning and inspection straightforward.

Vendor Comparison: Why Choose Our Customized Solutions

Choosing the right supplier for industrial grating is a critical decision impacting project timelines, budget, and long-term operational integrity. While many vendors offer standard grating, our specialization in Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating sets us apart. Below is a comparison showcasing our distinctive advantages:

| Feature | Our Customized Solution | Standard Grating Suppliers |

|---|---|---|

| Design Flexibility | Unlimited irregular shapes, curves, angles; integrates perfectly with complex layouts. | Limited to rectangular panels; requires on-site cutting/modification for irregular areas. |

| Engineering & Support | Dedicated engineering team, FEA analysis, 3D modeling, comprehensive technical drawings. | Basic load tables, minimal design support for custom requirements. |

| Material Options | Wide range of carbon, stainless steel (304, 316L), aluminum, specialized alloys. | Typically limited to common carbon steel with standard galvanization. |

| Precision & Fit | Factory-fabricated to exact dimensions, minimizing installation issues. | Field modifications often lead to imprecise fit, increased waste, and safety risks. |

| Project Cost Efficiency | Higher initial cost, but significant savings in installation labor, material waste, and long-term maintenance. | Lower initial unit cost, but often higher total project cost due to on-site issues. |

| Compliance & Certifications | Adherence to international standards (ISO, ANSI, ASTM) with verifiable test data. | May meet basic standards, but often lacks specialized certifications for complex designs. |

Our specialized approach ensures that every grating panel is a perfect fit, engineered for purpose, and delivered ready for installation, reducing both time and risk on complex industrial projects. We partner with clients from concept to completion, offering unparalleled expertise.

Customized Solutions: Tailored to Your Exact Needs

Recognizing that no two industrial projects are identical, our core strength lies in providing fully customized grating solutions. Our comprehensive customization process ensures that your Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating perfectly aligns with your operational, architectural, and safety requirements.

Our Customization Process Includes:

- Detailed Design Consultation: Collaborating with your engineers and architects to understand specific site conditions, load requirements, pedestrian/vehicular traffic, and environmental factors.

- Material & Finish Selection: Guidance on choosing the optimal steel grade (carbon, stainless, aluminum) and surface treatment (hot-dip galvanized, painted, powder-coated, electropolished) for corrosion resistance, aesthetics, and lifespan.

- Irregular Shapes & Cut-outs: Precision fabrication of custom contours, circular sections, angular platforms, and intricate cut-outs for pipes, columns, and machinery.

- Specialized Features: Integration of toe plates, nosings (e.g., checkered plate, abrasive-filled), stair treads, hinged sections, security caging, and access points.

- Attachment & Installation Systems: Designing bespoke fixing clips, hold-down devices, or welding preparations for secure and efficient installation.

- Engineering Validation: All custom designs are subjected to rigorous engineering analysis, including FEA, to confirm structural integrity and compliance with relevant loading codes and safety standards.

Application Case Studies

Our expertise in delivering Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating has empowered numerous industrial projects. Here are examples demonstrating the practical benefits:

Case Study 1: Large-Scale Petrochemical Complex

Client: Global Energy Solutions Inc.

Challenge: Design and install an extensive network of irregularly shaped walkways and maintenance platforms around complex pipe racks and processing units in a highly corrosive environment. Standard panels required excessive on-site cutting, leading to costly delays and compromised galvanization.

Solution: We provided over 2,500 square meters of custom-fabricated, hot-dip galvanized steel grating. Each panel was pre-cut and shaped in our facility based on detailed 3D models of the plant layout. Integrated cut-outs for pipe penetrations and structural supports were precisely engineered.

Outcome: Reduced installation time by 30%, eliminated on-site hot work, and ensured full corrosion protection due to factory galvanization. Client feedback highlighted significant cost savings and improved safety compliance. "The precision of their custom grating was exceptional, fitting perfectly even in the tightest spaces. A truly professional solution," stated the project manager.

Case Study 2: Municipal Wastewater Treatment Plant

Client: Metro Water Authority

Challenge: Replace deteriorating platforms and trench covers in an active wastewater treatment facility, requiring resistance to various chemicals and constant moisture, along with complex shapes to navigate around existing equipment. Minimal downtime was critical.

Solution: We designed and fabricated stainless steel (SS316L) grating panels, electropolished for maximum corrosion resistance and hygiene. Irregular panel shapes and custom cut-outs were pre-engineered to match the existing concrete infrastructure and process equipment. Quick-release fasteners were integrated for easy access to underlying services.

Outcome: The project was completed within the tight schedule, with seamless integration of new platforms. The enhanced corrosion resistance of the SS316L grating significantly extended the expected service life, minimizing future maintenance. The client reported a noticeable improvement in operational safety and ease of maintenance.

Authoritativeness & Trustworthiness: Our Commitment

Our dedication to quality, safety, and client satisfaction is underpinned by industry certifications, a proven track record, and transparent operational practices.

Certifications & Standards:

- ISO 9001:2015 Certified: Demonstrating a robust Quality Management System across all manufacturing processes.

- Compliance with ASTM, ANSI, BS, AS/NZS Standards: Ensuring product performance and safety meet international benchmarks.

- TÜV Rheinland Inspected Facilities: Regular third-party audits ensure adherence to European quality and safety standards.

Experience & Partnership:

With over two decades of specialized experience in metal fabrication, we have successfully partnered with leading enterprises in the petrochemical, power generation, and infrastructure sectors. Our client portfolio includes companies such as Siemens Energy, ExxonMobil projects, and numerous municipal utility providers, testament to our reliability and expertise.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for customized grating?

A: Lead times vary based on complexity and order volume. For standard customized designs, it's typically 3-5 weeks from drawing approval. Large-scale or highly complex projects may require 6-10 weeks. We provide a detailed project schedule upon order confirmation.

Q: Do you provide installation services or guidance?

A: While we primarily supply fabricated materials, we offer comprehensive installation guides, detailed drawings, and remote technical support. For larger projects, on-site supervision or training can be arranged.

Q: What is your warranty policy?

A: We offer a standard 5-year warranty against manufacturing defects and material failures under normal operating conditions. Extended warranties for specific applications and materials can be discussed.

Q: How do you handle design changes during the project?

A: Our flexible engineering team can accommodate design revisions. Any changes will be reviewed for impact on cost and schedule, with transparent communication and client approval before proceeding.

Lead Time & Fulfillment:

Our streamlined production process, combined with efficient logistics, ensures timely delivery. We work closely with clients to establish realistic timelines and provide regular updates on manufacturing progress and shipping. Expedited options are available for urgent requirements.

Warranty & Customer Support:

Beyond our product warranty, our commitment extends to comprehensive after-sales support. Our technical team is available for troubleshooting, maintenance advice, and addressing any queries that may arise post-installation. We believe in building long-term relationships through reliable service and product excellence.

Conclusion

The demand for sophisticated, adaptable, and highly engineered industrial infrastructure is only set to grow. Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating represents the pinnacle of modern industrial flooring solutions, offering unmatched precision, durability, and safety for the most demanding applications. By leveraging advanced manufacturing techniques, superior materials, and a deep commitment to client-specific needs, we deliver solutions that not only meet but exceed expectations, driving efficiency and safety across diverse industrial sectors.

References

- ASTM International. (2020). Standard Specification for Carbon Structural Steel. ASTM A36/A36M-20.

- ISO. (2009). Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. ISO 1461:2009.

- National Association of Architectural Metal Manufacturers (NAAMM). (2010). Metal Bar Grating Manual (MBG 531-10).

- Occupational Safety and Health Administration (OSHA). (1910). General Industry Standards: Walking-Working Surfaces. 29 CFR 1910 Subpart D.

- British Standards Institution. (2006). Grating panels. BS 4592-0:2006.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA