Feb . 18, 2025 08:07 Back to list

wire mesh standard size

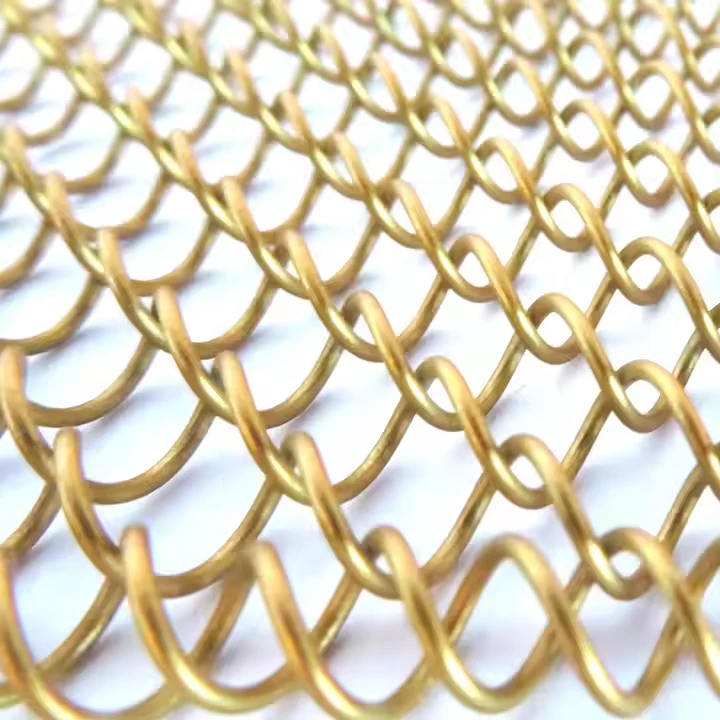

In industrial settings, choosing the right mesh size can improve system efficiency significantly. Filtration processes, for example, demand precise mesh sizes to allow only particles of specific dimensions to pass through. Standard mesh sizes such as 20x20 or 40x40 are used in air and liquid filtration systems, ensuring contaminant control while maintaining flow quality. This material's adaptability extends to the artistic realm, where sculptors and designers often employ wire mesh to create stunning, robust structures due to its flexibility and ease of manipulation. Here, the standard size may vary depending on the intricacy of the design, often involving finer mesh to achieve detailed features. For best practices, consulting with industry standards such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) is recommended. These bodies provide guidelines to ensure that the selected mesh size meets required safety and performance standards. In conclusion, the significance of understanding wire mesh standard sizes cannot be overstated. Each application demands a thoughtful consideration of mesh size and wire gauge to optimize the functionality and safety of the end product. As professionals continue to innovate with this versatile material, maintaining an awareness of the standard sizes available ensures up-to-date, informed decision-making in the selection process. With the right knowledge, wire mesh becomes a reliable ally across numerous applications, enhancing both the quality and effectiveness of industrial and creative projects alike. For those seeking to deepen their understanding or need specific recommendations, collaboration with experts in wire mesh production ensures the best fit for your project's requirements. Their expertise in tailoring solutions to unique applications provides assurance of achieving both structural integrity and aesthetic appeal.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA