Jan . 09, 2025 12:26 Back to list

wire mesh manufacturers

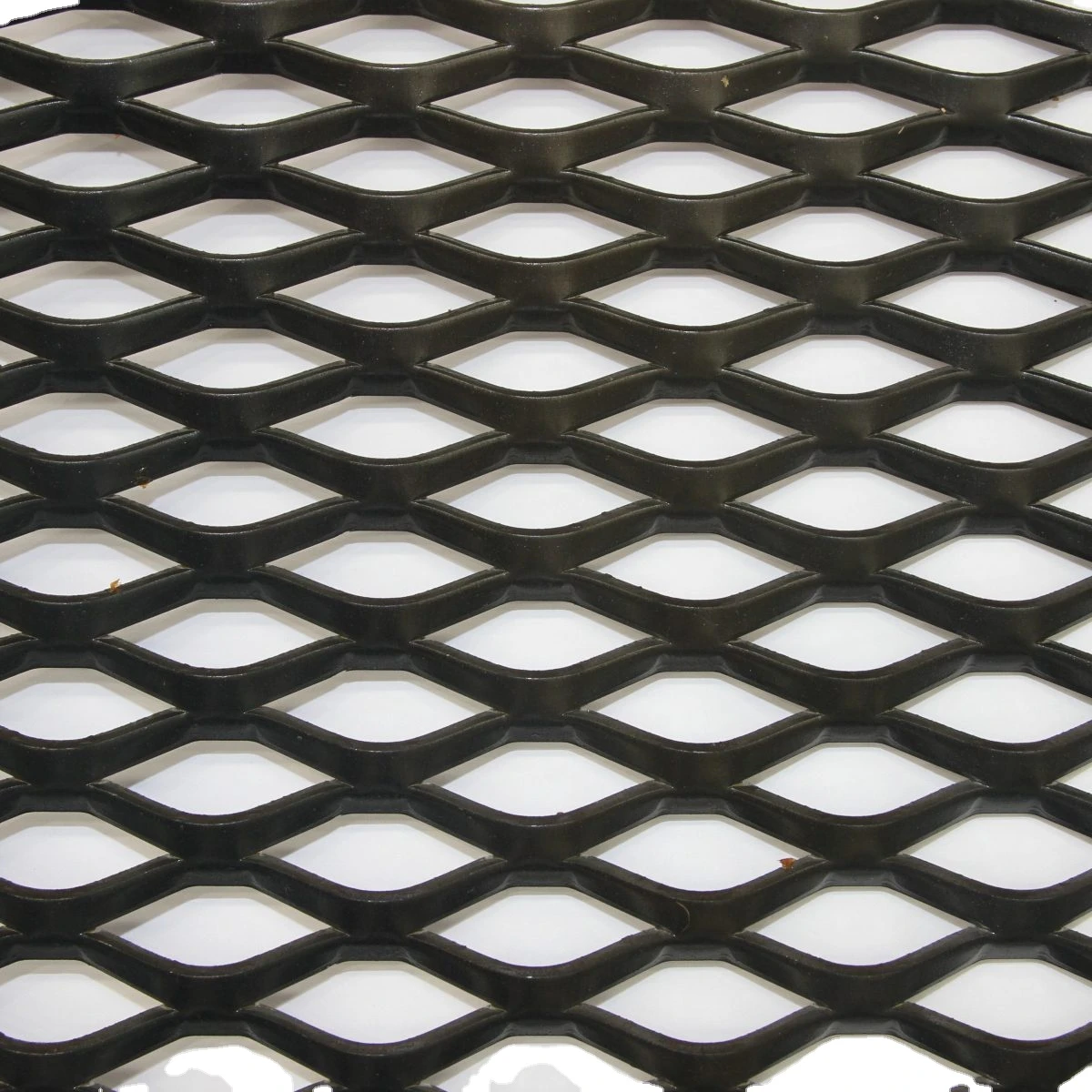

Another hallmark of leading wire mesh manufacturers is their experience in catering to diverse client needs. Their portfolios often showcase a wide range of customized solutions, tailored to meet specific project requirements. From architectural wire mesh used in modern building facades to the robust fencing solutions designed for agricultural fields, their ability to innovate and adapt highlights years of industry knowledge and client collaboration. Trustworthiness is often built through transparency and customer service. Reliable manufacturers offer comprehensive pre-sale and post-sale support, including technical advice, installation guidance, and maintenance tips. Their commitment to fostering long-term relationships with clients is evidenced by responsive communication channels and robust warranties, ensuring customer peace of mind. In a competitive market, leading wire mesh manufacturers distinguish themselves not only through product quality but through a holistic approach characterized by experience, expertise, commitment to international standards, and unwavering customer support. Their ability to combine cutting-edge technology with a deep understanding of market needs makes them invaluable partners across industries looking to harness the multifunctional potential of wire mesh products. In conclusion, the global landscape of wire mesh manufacturing is sculpted by a few distinguishing factors that separate the leaders from the rest. The perfect blend of advanced technology, adherence to rigorous standards, and a customer-focused approach ensures these manufacturers not only deliver superior products but also provide an authoritative and trustworthy service to all sectors requiring wire mesh solutions. Whether for security, aesthetics, or functional purposes, collaborating with such experienced producers guarantees products that meet the highest expectations and project requirements.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

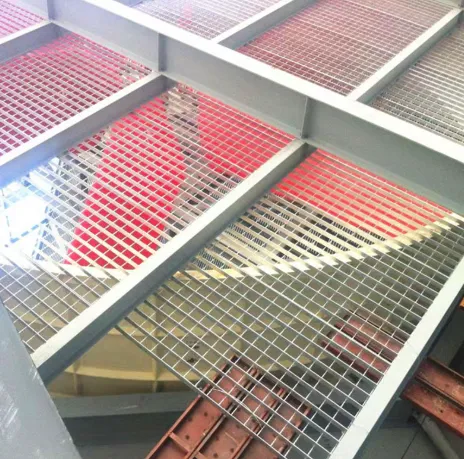

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA