Feb . 17, 2025 22:50 Back to list

wire mesh for sale

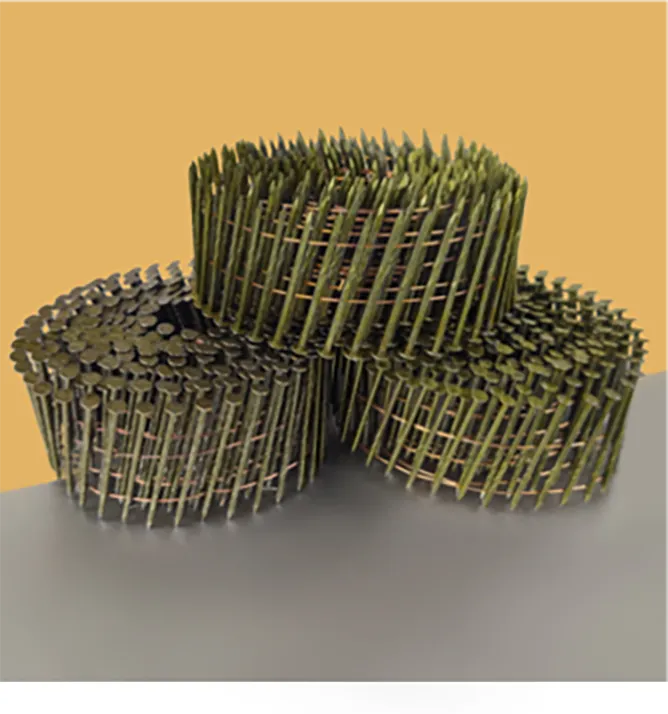

Authoritativeness is evident in the extensive use of wire mesh across reputable industries. From civil engineering projects such as bridges and tunnels to security fences and wildlife enclosures, wire mesh’s adaptability is undisputed. Leading manufacturers invest in continuous research and development, optimizing designs to meet evolving industry standards and environmental regulations. These advances not only improve product performance but also contribute to sustainability efforts, a key consideration in today’s construction landscape. Trustworthiness in choosing wire mesh involves selecting suppliers with a proven track record. Reputable companies offer certifications attesting to the quality and compliance of their products with international standards. They provide comprehensive support, from technical specifications to installation guidance, ensuring customers can rely on their materials to meet project requirements. Testimonials and case studies often highlight past successes, offering reassurance of the supplier’s capability to deliver results. The market for wire mesh also includes innovations such as pre-crimped mesh, which undergoes a unique crimping process before weaving, increasing its stability for demanding applications. Furthermore, advancements in manufacturing techniques allow for customization, enabling clients to specify dimensions, shapes, and coatings that best suit their projects. Environmental consciousness drives manufacturers to adopt sustainable practices, such as using recyclable materials and minimizing waste, aligning with growing consumer demand for eco-friendly solutions. In summary, wire mesh is a cornerstone material across various sectors, appreciated for its strength, versatility, and adaptability. Selecting the right mesh involves consideration of material properties, application requirements, and installation methods. Relying on expert guidance and proven suppliers enhances trust in the product's quality. With ongoing innovations and a commitment to sustainability, wire mesh continues to evolve, meeting the needs of contemporary projects while maintaining its status as a reliable material for diverse applications.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA