Jan . 09, 2025 14:08 Back to list

wire mesh factory

Trustworthiness is the bedrock of any wire mesh factory. Clients rely heavily on the integrity and consistency of the products supplied. This trust is built over time through transparency in operations, adherence to international standards, and a commitment to customer satisfaction. A trustworthy wire mesh factory provides detailed product documentation and certifications, offering clients peace of mind about the authenticity and quality of their purchases. The importance of a wire mesh factory in modern infrastructure cannot be overstated. These products are integral to building safe and sustainable environments. In construction, wire mesh is essential for reinforcing concrete structures, ensuring stability and longevity. In agriculture, wire mesh is utilized for fencing and animal enclosures, providing security and durability. In industrial settings, they serve as filters and sieves, indispensable in processes such as separation and filtration. Ultimately, the value proposition of a wire mesh factory lies in its unwavering commitment to delivering superior products that meet the evolving needs of various industries. By combining experience, expertise, authoritativeness, and trustworthiness, these factories not only uphold industry standards but continually push the envelope, driving progress and innovation. Choosing a wire mesh factory with these attributes is paramount for businesses seeking quality and reliability. As the world continues to evolve, the demand for high-quality wire mesh products will only increase, underscoring the pivotal role these factories play in shaping the future of manufacturing and infrastructure.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

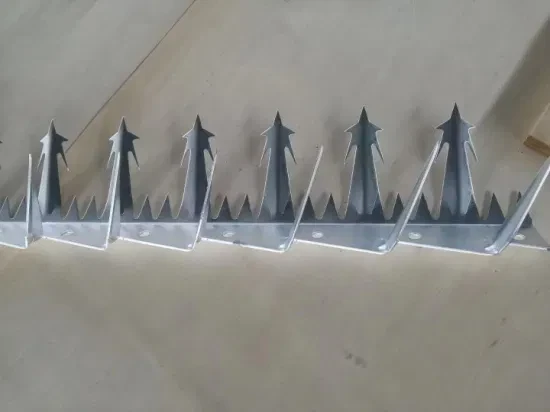

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA