Dec . 03, 2024 14:29 Back to list

Welded Wire Mesh Reinforcement for Enhanced Structural Support and Durability

The Importance of Welded Mesh Reinforcement in Modern Construction

Welded mesh reinforcement has become an integral part of modern construction, providing essential support and stability to various structures. This innovative technique leverages the strength of steel mesh, which is formed by welding together wires at intersections, creating a robust grid that enhances the load-bearing capacity of concrete and other materials. In this article, we will explore the advantages of welded mesh reinforcement, its applications, and why it is increasingly favored in contemporary building practices.

Understanding Welded Mesh Reinforcement

Welded mesh, also known as welded wire reinforcement (WWR), is manufactured from high-quality steel wires that are arranged in a grid pattern and welded together at their intersections. This method of construction offers numerous benefits, including improved tensile strength, durability, and resistance to cracking. The uniformity of welded mesh ensures that the forces acting on the concrete are evenly distributed, minimizing the risk of structural failure.

The use of welded mesh in reinforcement has gained popularity not only due to its physical properties but also because of its versatility. It can be produced in various shapes and sizes to accommodate different construction needs, making it suitable for a wide range of applications, from residential buildings to large-scale infrastructure projects.

Key Advantages of Welded Mesh Reinforcement

1. Enhanced Strength and Durability One of the primary benefits of using welded mesh is the significant increase in tensile strength it provides to structures. Compared to traditional reinforcement methods, welded mesh delivers improved resistance to tensile and shear forces. This means the structures can carry heavier loads, making them ideal for high-rise buildings, bridges, and other critical infrastructure.

2. Cost-Effectiveness While the initial cost of welded mesh reinforcement may be higher than some traditional methods, the long-term savings it offers can be considerable. The speed of installation reduces labor costs, while the improved durability and reduced maintenance needs lead to lower overall expenses. In many cases, the use of welded mesh can result in substantial savings over the lifespan of the structure.

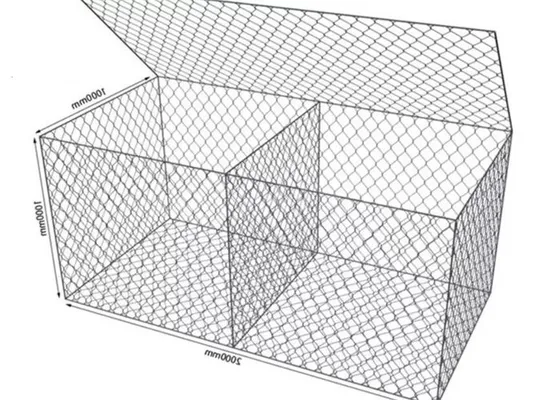

welded mesh reinforcement

3. Uniformity and Consistency The manufacturing process for welded mesh ensures a consistent quality and uniformity across the sheet. This reduces the risk of human error during installation and ensures that the reinforcement performs as intended. Additionally, the consistent spacing of the mesh allows for better concrete flow and bonding, leading to higher-quality finishes.

4. Flexibility in Design Welded mesh can be easily adapted to meet specific design requirements. It can be cut and shaped to fit various forms and dimensions, making it suitable for a variety of construction applications. This flexibility allows architects and engineers to innovate with their designs without compromising structural integrity.

5. Environmental Impact Using recycled materials in the production of welded mesh can contribute to more sustainable construction practices. Steel is one of the most recycled materials globally, and incorporating welded mesh into construction helps reduce the overall carbon footprint of building projects.

Applications of Welded Mesh Reinforcement

Welded mesh finds applications across a broad spectrum of construction projects. Its uses include

- Floors and Slabs Providing support in both residential and commercial buildings. - Walls and Foundations Offering enhanced stability and resistance to cracking. - Parking Garages Supporting heavy traffic loads. - Bridges and Dams Critical for safety and longevity in civil engineering projects.

Conclusion

As the construction industry continues to evolve, the importance of materials that enhance strength, reduce costs, and support sustainable practices becomes increasingly apparent. Welded mesh reinforcement stands out as a superior choice for modern construction, combining practicality, efficiency, and reliability. Its positive impact on the durability and performance of structures makes it a vital consideration for engineers, architects, and builders alike. Embracing welded mesh technology will not only improve current building practices but also pave the way for safer and more resilient infrastructure in the future.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA