Jan . 22, 2025 02:39 Back to list

fiber mesh for waterproofing

Market forces, such as demand and raw material availability, introduce another layer of complexity in pricing mechanisms. A surge in construction projects could elevate demand, consequently inflating prices. Similarly, fluctuations in global steel prices due to geopolitical factors or economic conditions can lead to unpredictable shifts in walkway mesh costs. Awareness of these market conditions allows for strategic purchasing, potentially securing better deals during market downturns or sourcing alternative materials during price surges. Recognizing the specialization and customization that may be required further influences pricing. Custom mesh sizes or additional treatments, such as powder coating for aesthetics and additional protection, can escalate the base price. Though these customizations ensure the mesh aligns perfectly with project requirements, evaluating the necessity against cost implications is prudent. By synthesizing trends, material choices, manufacturing processes, and market dynamics, professionals can approach walkway mesh purchasing with an informed perspective. This awareness not only ensures optimal material selection for specific applications but also allows for strategic financial planning in project budgeting. Bridging expertise with real-time market analysis forms the cornerstone of successful procurement strategies in the dynamic world of walkway mesh.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

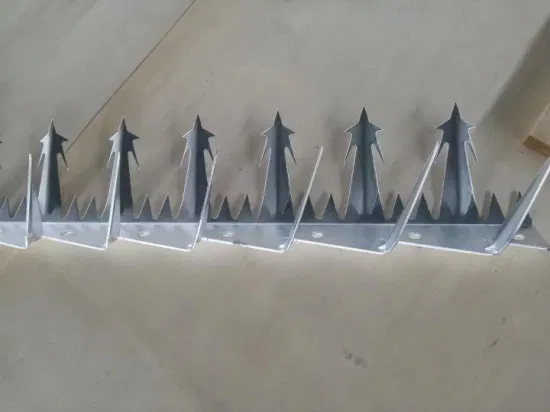

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA