Mar . 05, 2025 03:25 Back to list

types of welded wire mesh

Another specialized type is Industrial Welded Wire Mesh. Designed to withstand heavy loads and stress, this type features thicker wires and smaller grid sizes, offering enhanced strength and stability. It is commonly used in concrete reinforcement, pre-cast concrete elements, and other heavy-duty manufacturing processes. The robust nature of industrial mesh ensures structural integrity and durability, making it a trusted choice for major construction projects. For those in agriculture, the Welded Livestock Mesh stands out as a preferred option. Designed specifically for the containment of livestock, this type is crafted with humane and secure animal handling in mind. The mesh design prevents animals from injury while providing robust boundaries. This type often features a tighter weave and stronger wires to accommodate larger animals and resist impact. Considerations when choosing a type of welded wire mesh include the specific application, environmental conditions, budget constraints, and required longevity. Proper selection ensures that the wire mesh will serve its intended purpose effectively, whether offering security, enhancing structural stability, or resisting environmental deterioration. In summary, the diversity available in the types of welded wire mesh allows for tailored solutions that meet specific application requirements. Expert knowledge and experience guide the choice of the appropriate type, balancing cost, performance, and durability. By understanding the distinct advantages each type offers, stakeholders can ensure they select the most effective solution for their needs, ensuring safety, efficiency, and cost-effectiveness in their projects.

Latest News

-

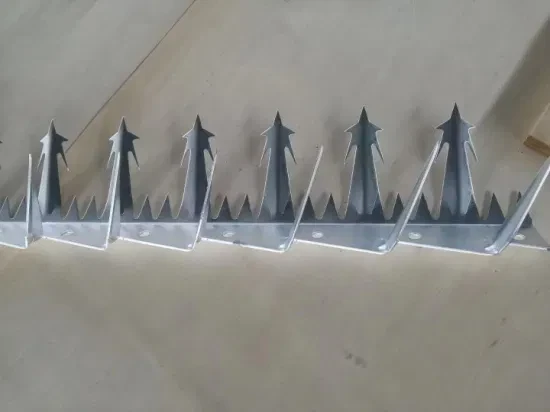

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA