Jan . 14, 2025 10:36 Back to list

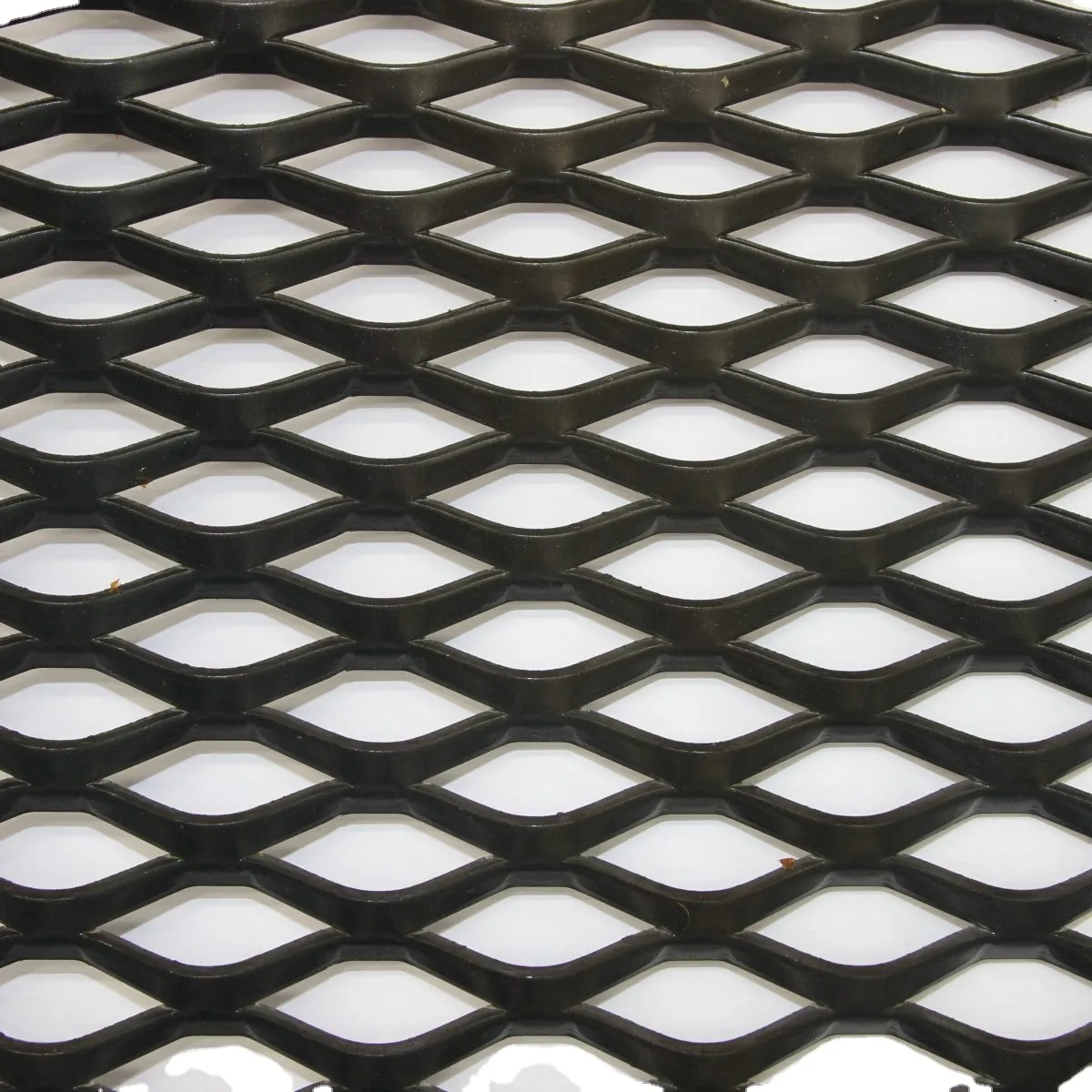

type 19 4 grating

Professional insight into its expertise showcases Type 19 4 Grating as a preferred choice in scenarios requiring low maintenance and high safety standards. Its sturdy build ensures minimal bending or distortion under pressure, a critical requirement for areas expecting heavy foot traffic or mechanical impact. Its cross-sectional design provides excellent load management, ensuring safety and structural integrity at all times. This type of grating is particularly favored in industrial zones where safety regulations are stringent, providing peace of mind to facility managers and operators. The authoritativeness of choosing a Type 19 4 Grating owes much to its longstanding effectiveness in the field. Engineers and architects often lean on this solution, knowing it has stood the test of time in both functional performance and compliance with industry standards. Many regulatory bodies recognize this specification as meeting essential safety criteria, which in turn, solidifies its standing as a reliable choice for various projects. Trustworthiness is inherent in the Type 19 4 Grating, particularly when sourced from reputable manufacturers. Quality assurance checks and adherence to industry standards ensure that each piece of grating meets the required specifications and performs as expected under stress. Users can rely on the grating's ability to withstand harsh conditions without compromising safety or functionality. In summation, the Type 19 4 Grating is more than just a patterned metal lattice; it represents a confluence of design innovation, material excellence, and trust in industrial applications. Its practical advantages solidify its place as a mainstay in the realm of structural solutions. Decisions to implement such a solution should be made with careful consideration of the specific environment and application needs, always ensuring that the grating chosen not only meets but exceeds the demands of its intended use. This strategic insight into the Type 19 4 Grating enables businesses to fortify their operations with a product that is synonymous with strength, safety, and durability.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA