Jan . 13, 2025 13:05 Back to list

trench drain grate

From an authority standpoint, adherence to local regulations and industry standards is non-negotiable. Ensuring compliance with ASTM or EN specifications validates the trench drain grating's suitability for specific applications, reflecting a commitment to safety and quality. Experts in the field advocate for regular maintenance checks and prompt repairs to any damages, extending the life of the system and maintaining its effectiveness. Trustworthiness is reinforced through credible testimonials and documented case studies. Learning from other successful implementations provides insights into potential pitfalls and strengthens confidence in the performance of chosen solutions. Collaborating with manufacturers or suppliers known for their rigorous quality controls and innovative designs instills further assurance in end-users. Ultimately, the journey of selecting and installing trench drain grating is multifaceted, demanding thoughtful consideration of materials, design, installation, regulation adherence, and ongoing maintenance. Leveraging accumulated experience and insights from experts in the field ensures that drainage systems not only meet but exceed expectations, delivering reliable and efficient water management solutions tailored to specific environmental conditions and application demands.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

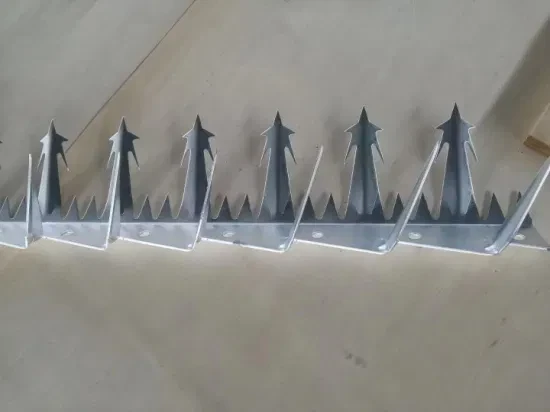

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA