Jan . 16, 2025 03:42 Back to list

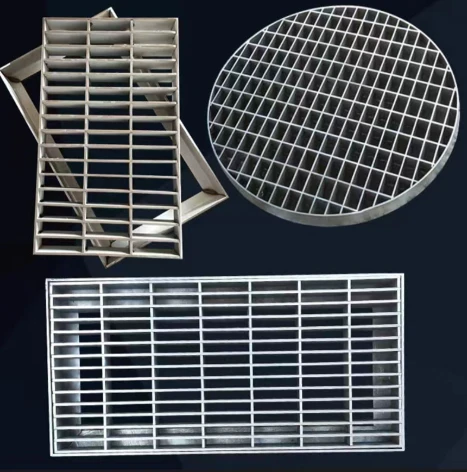

galvanized grating

The expertise of manufacturers in this field ensures that each grating product meets the specific standards required for different environments. Adhering to regulations such as the American Association of State Highway and Transportation Officials (AASHTO) guidelines, these products are engineered to withstand substantial weight loads and environmental stressors. Manufacturers often perform rigorous testing to validate these product capabilities, demonstrating commitment to quality and performance. Authoritativeness in this domain comes from decades of practical application and continuous product improvement. As industries evolve, so do the requirements for safety and efficiency. Structural grating manufacturers frequently engage in research and development to innovate and enhance their product offerings. This innovation leads to new solutions like modular grating systems that allow for easy configuration and reconfiguration, thereby meeting the dynamic needs of modern industrial operations. Trustworthiness is cemented through successful case studies and testimonials from companies that have used structural grating in demanding projects around the globe. An established track record, combined with adherence to international quality standards, reassures clients of the credibility and reliability of these products. For businesses exploring structural grating solutions, understanding the nuances and benefits of each material type is crucial for making informed decisions. Whether prioritizing weight reduction, corrosion resistance, or load-bearing capacity, structural grating offers a comprehensive solution tailored to meet these demands, thereby driving efficiency and safety in industrial applications.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA