Mar . 07, 2025 07:19 Back to list

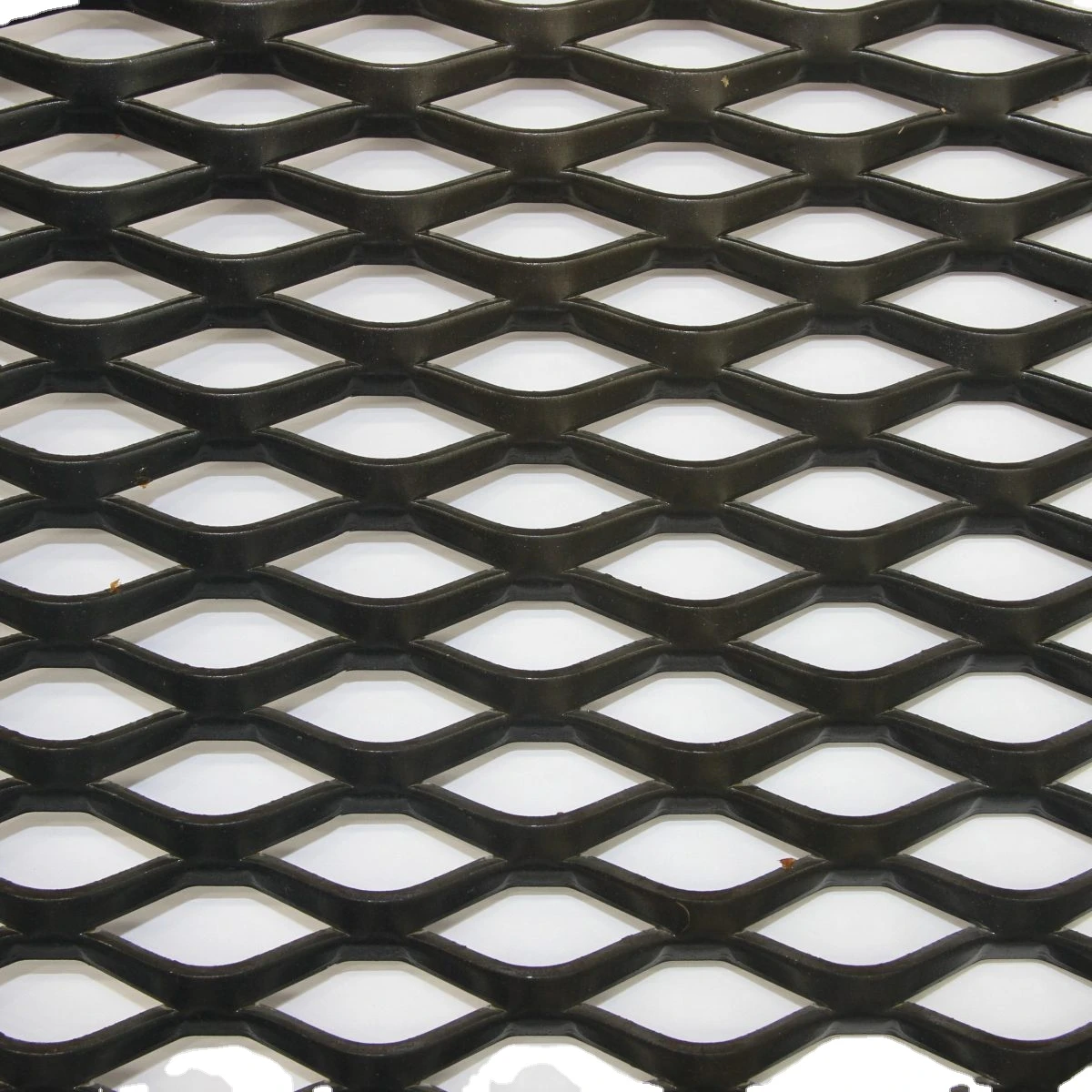

steel mesh for concrete slab

Durability is another significant advantage offered by steel mesh in concrete slabs. Its resistance to environmental factors such as moisture and temperature fluctuations ensures longevity, even in adverse conditions. The protective zinc coating commonly applied to steel mesh guards against corrosion, a frequent concern in regions with high humidity or salinity. In my professional experience, recommending steel mesh with an appropriate protective coating is a critical step in project planning, especially for outdoor settings exposed to harsh weather elements. Engineers, architects, and builders recognize the undeniable advantages associated with steel mesh. Beyond just a reinforcement tool, it stands as a symbol of modern engineering's capability to merge traditional materials with contemporary technology. By implementing steel mesh in concrete slab projects, stakeholders can anticipate reduced maintenance requirements, leading to a long-term reduction in operational costs and an increase in overall structural reliability. A reflective understanding of the integration of steel mesh in concrete slabs highlights its significance not only from an engineering perspective but also from a sustainability standpoint. The prolonged durability and reduced need for repairs ultimately contribute to lower material consumption and waste production over time—a growing concern in today's environmentally-conscious world. In conclusion, for those involved in the planning, designing, and execution phases of construction projects, steel mesh for concrete slabs represents a methodological choice that combines expertise, authority, and trustworthiness. The advanced understanding and consistent application of this material reflect a profound commitment to quality, safety, and sustainability in construction, affirming its value in both current and future building endeavors.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA