Jan . 21, 2025 01:58 Back to list

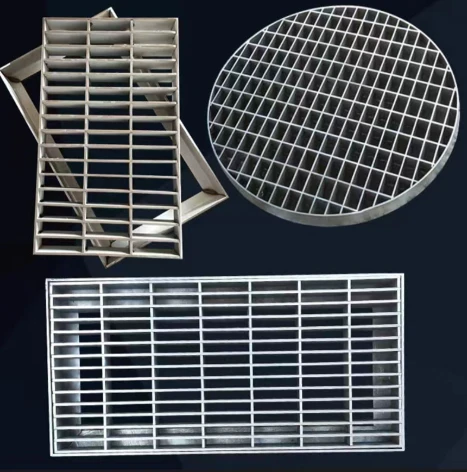

steel grating price

On the macroeconomic front, fluctuations in global steel prices due to changes in supply and demand dynamics also affect grating prices. For instance, tariffs, trade policies, and the availability of raw materials can lead to increased production costs, which are ultimately passed down to the consumer. Additionally, logistical considerations such as shipping costs and delivery times are influenced by international market conditions and can impact the final pricing structure. Beyond these tangible components, innovations in steel grating technology and sustainability initiatives have begun to influence prices. Companies investing in sustainable production practices may face higher upfront costs, yet they often appeal to environmentally conscious consumers, adding a premium to their products. Furthermore, technological advancements in corrosion protection, such as galvanization techniques, may also alter pricing. Understanding these pricing factors is crucial for stakeholders to navigate the market effectively. For businesses, strategic procurement practices, such as building relationships with multiple suppliers and staying attuned to market trends, can mitigate price volatility. For consumers, evaluating the total cost of ownership rather than just the initial purchase price can lead to more economical and sustainable decisions in the long run, especially for projects where maintenance and longevity are paramount. In conclusion, the steel grating market is influenced by a complex interplay of materials, manufacturing processes, and economic factors. By leveraging insights into these areas, businesses can better predict pricing trends and make strategic decisions that align with their operational needs and budget constraints. As the market evolves, continuous monitoring and adaptation remain essential to maintain competitiveness and ensure the best outcomes for all parties involved.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA