Jan . 22, 2025 04:11 Back to list

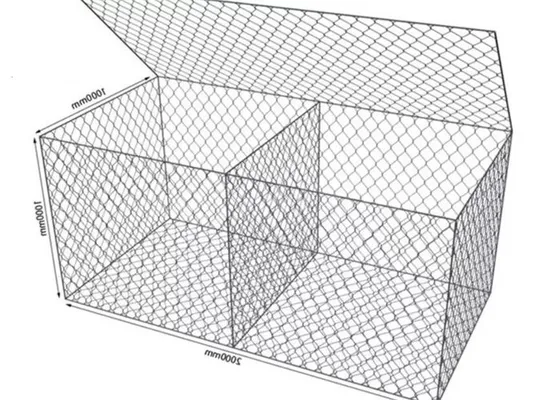

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

At a more granular level, the specification of grating is often detailed by bar thickness, pitch, load capacity, and finishing style. The bar thickness and pitch directly affect the load capacity and safety features, crucial for engineering applications requiring precise load distribution and human safety assurance. Finishing options, including electropolishing or coating, enhance the grating's resistance to environmental factors and contribute to its longevity and appearance. A decade-long record of specialized application reveals that a successful project often hinges on the accurate cochlear alignment between product and practice. It’s not uncommon to witness enhancements in operational efficiency and workplace safety attributed to selecting the correct stainless steel grating specification. An engineering marvel designed with meticulous measurements and compositions can drastically reduce maintenance costs and increase lifecycle performance. Trustworthiness stems from adhering to international standards and certifications. Reputable manufacturers engage with engineering teams to ensure gratings meet specifications laid out by industry standards such as ASTM, ASME, or OSHPD. These standards not only assure quality but also deliver peace of mind to clients investing in infrastructure that must perform unerringly over time. In summary, the specification for stainless steel gratings encompasses more than dimensions and grades; it is an assurance of quality, performance, and longevity. Leveraging in-depth knowledge and experience in the selection and application of stainless steel gratings significantly impacts both the functional outcome of projects and the foundational strength of a site's SEO strategy. As the steel grating market evolves, staying informed about innovative materials and techniques enhances the competitive edge, elevating a seemingly conventional product into an exemplary standard of industrial and commercial utility.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA