Jan . 20, 2025 14:25 Back to list

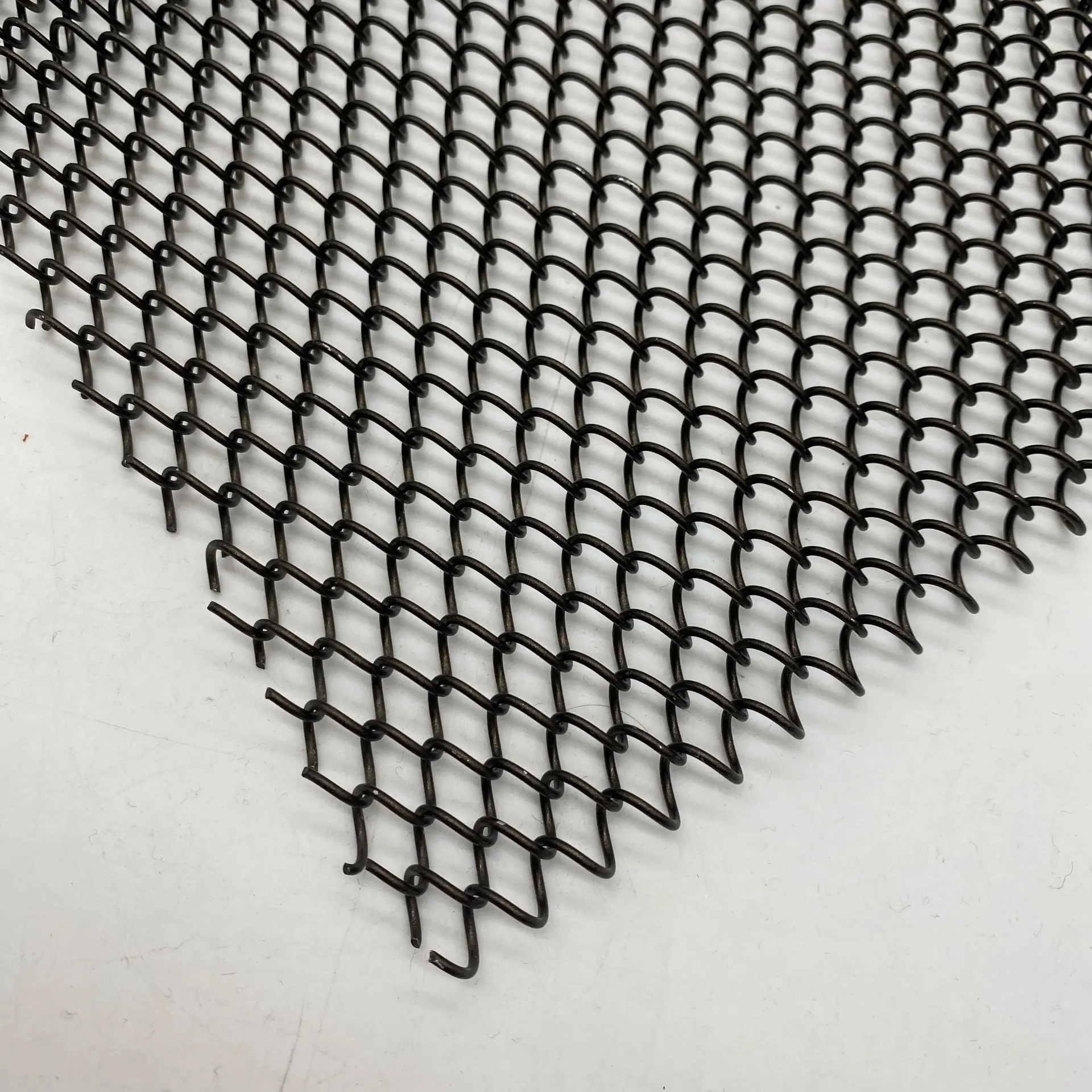

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

In today's eco-conscious world, stainless steel's recyclability adds another feather to its cap. This sustainability factor, coupled with its low maintenance cost due to its resistance to wear and tear, makes it an economically sound investment. Facility managers often report substantial savings over time as SS floor grating requires less frequent replacements compared to other materials, validating its cost-effectiveness in long-term infrastructure planning. Implementing SS floor grating in architectural designs also unlocks new aesthetic possibilities. Its sleek and modern appearance can enhance both industrial plants and commercial spaces, providing a functional yet appealing solution. This aesthetic versatility encourages architects to incorporate SS floor grating not just for utility, but also for creative architectural expression. Trustworthiness, a core attribute for any building material, is exemplified by SS floor grating through rigorous quality standards and industry certifications. When sourced from reputable manufacturers, these gratings adhere to strict safety and performance benchmarks, ensuring that end-users receive a product that meets and often exceeds expectations. This dependability fosters confidence among industry stakeholders who prioritize safety and quality. To sum up, SS floor grating stands as a paragon of strength, versatility, and durability. Its comprehensive offerings meet the demanding requirements across industries, ensuring both safety and aesthetic value. For any project aiming to blend functionality with enduring performance, SS floor grating undoubtedly represents a wise and strategic choice. With a track record of reliability and excellence, it continues to be a cornerstone in the foundations where safety and trust are paramount.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA