Feb . 13, 2025 05:19 Back to list

sheetrock corner

Furthermore, the use of a specialized corner trowel can simplify the task and enhance precision. This tool ensures even application and reduces the margin for human error—something every professional endorses. A colleague once shared how an investment in high-quality trowels significantly improved their corner finishes and reduced material wastage, underlining the correlation between tool quality and performance outcome. Beyond the physical installation, finishing the sheetrock corners demands a keen eye for detail. Sanding, though laborious, is non-negotiable. It transitions a seemingly rugged installation into a smooth, paint-ready surface. Experts stress the importance of using fine-grit sandpaper and caution against over-sanding, which can undo the hard work and compromise the wall’s integrity. In terms of trustworthiness, hiring or consulting with seasoned professionals for insight cannot be overstated. As an authority in the domain, I can attest to the myriad of nuances that textbooks may not cover. For example, humidity levels in a room can affect the drying time of compounds and potentially the longevity of the corners. Such factors are best handled with experience-guided judgment. In conclusion, the mastery of sheetrock corners blends both science and art. It requires a foundational understanding of materials, steadfast adherence to technique, and an openness to learning through experience. Those who endeavor to fully grasp sheetrock corner installation will find the satisfaction of finishing a project that stands the test of time and aesthetics—a reflection of expertise and quality. Ultimately, by blending professional insights with practical experiences, one can achieve an unbeatable finish that sets their work apart. Deliberate attention to these details not only ensures customer satisfaction but also enhances the reputation of one's craft, establishing a legacy of quality and trustworthiness in the world of construction.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

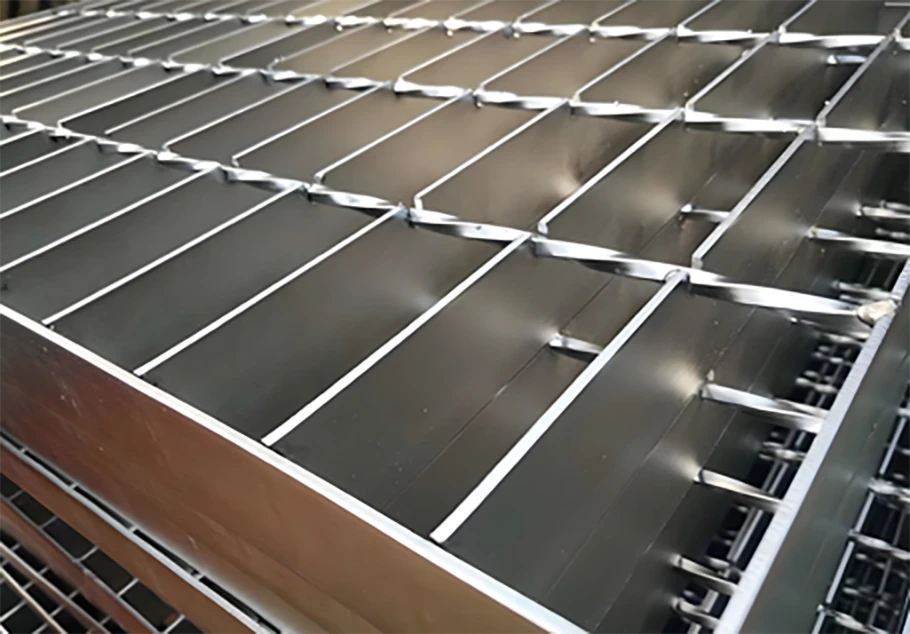

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA