Jan . 20, 2025 13:15 Back to list

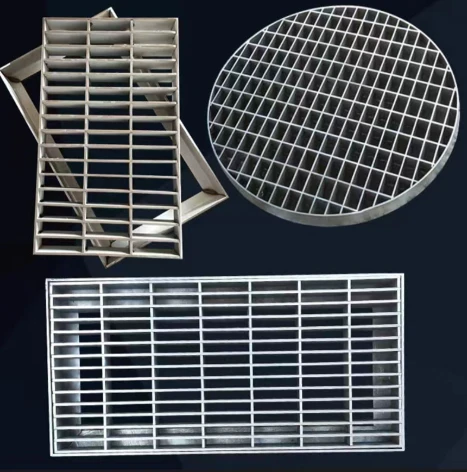

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Real-world experiences highlight the transformative impact that well-chosen and properly maintained shearing shed grating can have on agricultural productivity. Farmers report more streamlined operations, resulting in faster shearing times and reduced stress levels for the sheep. The installation of high-quality grating has also been linked to fewer accidents and injuries, both to the animals and the operators, underscoring the importance of investing in superior materials and professional installation services. The authority of a shearing shed grating provider can often be gauged by the certifications and quality guarantees they offer. Reputable manufacturers often adhere to stringent industry standards and provide warranties that reflect their confidence in the product's durability and performance. Partnering with such manufacturers not only assures quality but also positions farmers to manage their operations with an added layer of trust. In building a strong foundation of trust with customers, transparent communication from the suppliers about the benefits, installation processes, and maintenance of shearing shed grating is vital. Farmers are encouraged to seek out providers who offer comprehensive support services, from consultation to post-installation assistance, ensuring that all operational challenges are swiftly addressed. By focusing on the Experience, Expertise, Authoritativeness, and Trustworthiness—or E-E-A-T principles—users can enhance their operations considerably. From selecting the optimal material to professional handling and maintenance, every decision regarding shearing shed grating can significantly influence the welfare of the sheep and the efficiency of agricultural processes. Ultimately, investing in high-quality grating is not just about meeting an immediate need, but also about securing long-term operational success and sustainability in the ever-evolving agricultural landscape.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA