Jan . 16, 2025 05:12 Back to list

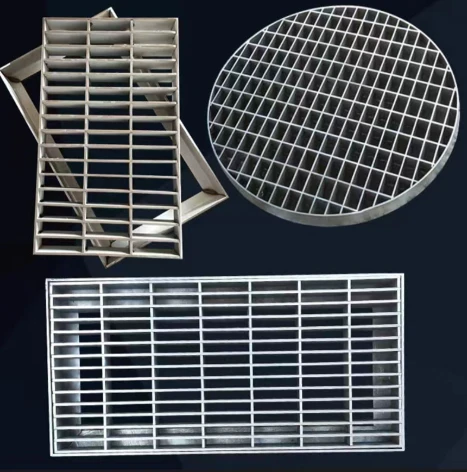

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Reflecting on real-world experience, one can appreciate the critical operational testing that gratings undergo before installation. Trials conducted in varying weather conditions and geographical locations allow engineers to gauge performance metrics, ensuring that each grating system adheres to high standards of reliability. This rigorous testing process highlights the industry's commitment to trustworthiness, reinforcing confidence in the products they provide. Moreover, custom solutions designed for different types of roads and regions illustrate the expertise and adaptability within the industry. Urban areas may require different grating specifications compared to rural roads, demanding a bespoke approach in design. By analyzing traffic patterns, environmental factors, and regional weather data, experts can offer products tailored to specific needs, enhancing safety where it is most needed. In conclusion, the unnoticed yet vital role of road safety gratings emphasizes their critical contribution to road safety. From the selection of high-grade materials to the intricate design and compliance with global safety standards, every facet reflects a dedication to ensuring drivers’ safety across the world. These covert protectors of the road, backed by expert engineering and time-tested authority, continue to evolve alongside advancements in technology and safety research, ensuring that as the world advances, so does road safety.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA