Jan . 15, 2025 04:52 Back to list

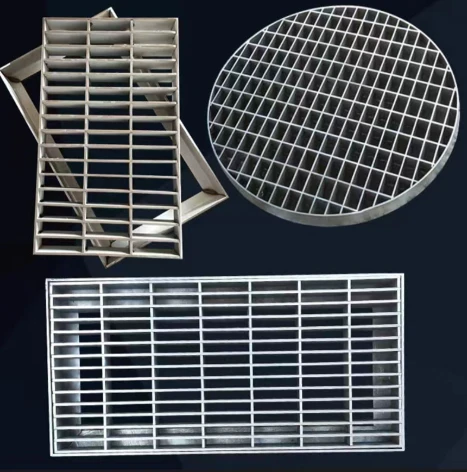

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Experience-driven selection of road gully gratings typically involves assessing specific needs such as load rating, grate opening, and environmental conditions. Experienced planners consider factors like the local climate, potential for debris accumulation, and ease of maintenance. A well-chosen grating ensures optimal functionality and longevity, minimizing maintenance costs and potential road hazards. Expertise informs the ongoing development and innovation within the industry. Research into new materials, like polymer composites or lightweight metals, is continually advancing to offer solutions that meet the growing demands of modern cities. These materials promise increased strength, reduced weight, and enhanced corrosion resistance, contributing to sustainability goals by potentially reducing the environmental impact of raw material extraction and manufacturing processes. Finally, the interplay between technology and craftsmanship in producing road gully gratings illustrates a blend of tradition and innovation. The precision involved in casting and finishing, done frequently with computer-aided design and manufacturing supervision, stands as a testament to the expertise rooted in both history and the cutting edge of technological development. Overall, the world of road gully gratings reveals a profound narrative about urban engineering, sustainability, and the continual pursuit of excellence. Whether dictated by regional policies or driven by innovative manufacturers redefining through research and development, the evolution of road gully gratings is a reflection of society's ability to adapt and enhance infrastructure for the future.

Latest News

-

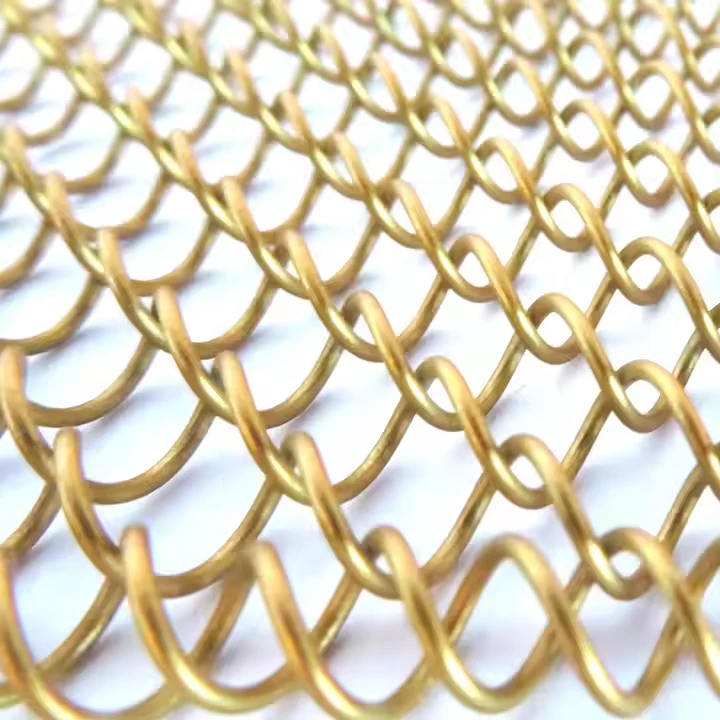

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA