Jan . 20, 2025 11:45 Back to list

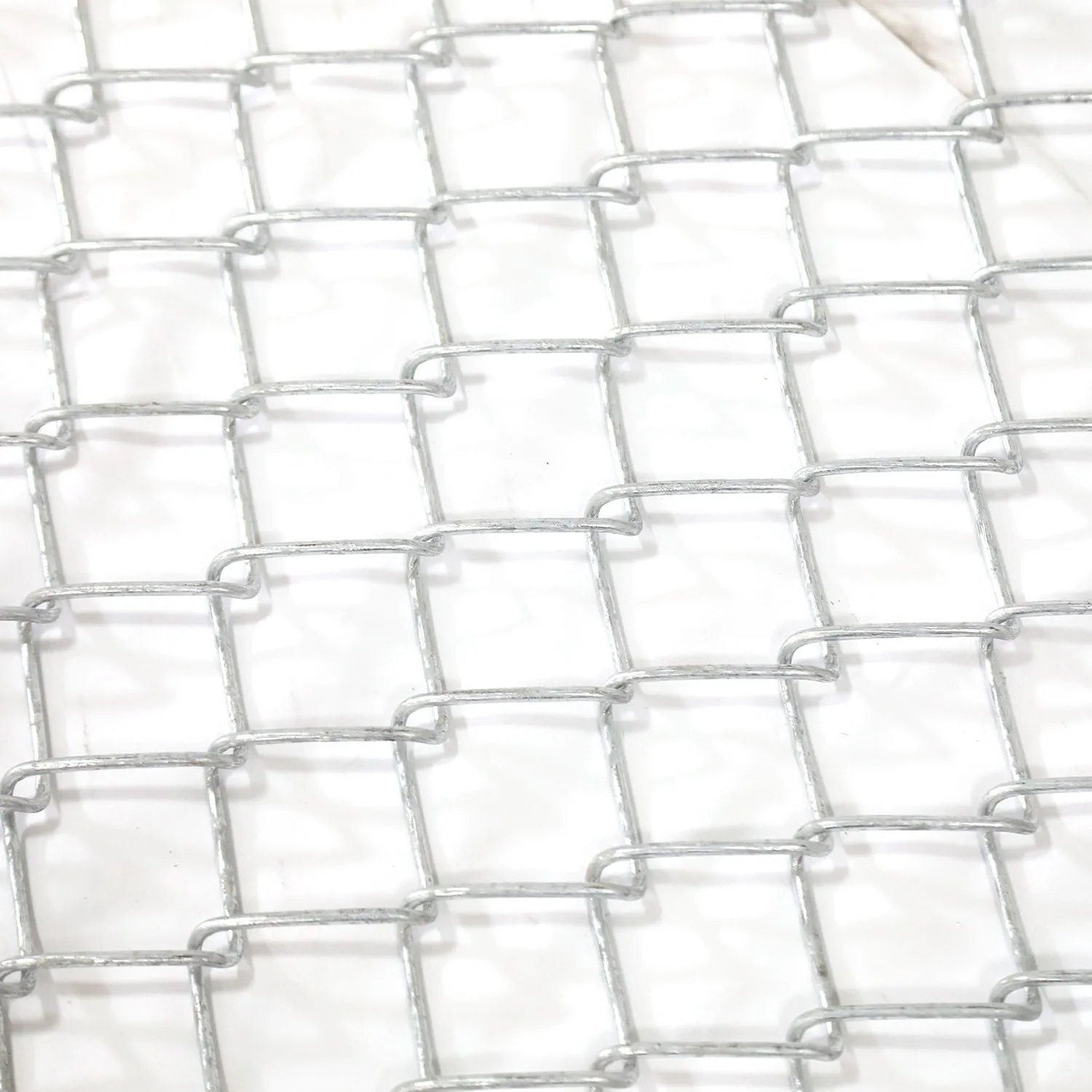

galvanized grating

Trustworthiness in the installation of riveted grating is achieved through rigorous quality control and adherence to established manufacturing protocols. Reputable manufacturers conduct exhaustive testing, including load tests and corrosion resistance assessments, to certify that their products can survive the harshest conditions. This unwavering commitment to quality ensures that customers continue to trust riveted grating for critical applications in chemical plants, oil refineries, and office buildings alike, where trust in materials equates to trust in safety and longevity. The evolution of riveted grating technology continues as experts innovate to meet new challenges. The introduction of materials that resist specific chemical exposures or those that offer additional corrosion protection continue to broaden its application. Sustainability has also become a focal point, with eco-friendly materials and recyclable options gaining traction. These advancements demonstrate a commitment not just to the present functionality of riveted grating but to its future potential as industries evolve. For those seeking comprehensive solutions in industrial and architectural engineering, riveted grating represents a blend of experience, expertise, authoritativeness, and trustworthiness. It is a product born from necessity, honed through innovation, and proven through decades of implementation. Choosing riveted grating assures stakeholders of unrivaled performance and an investment in quality that adroitly tackles the challenges of modern infrastructure and industrial applications. Behind every installation is a legacy of craftsmanship and reliability, affirming its place as a cornerstone in the world of materials engineering.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA