Mar . 06, 2025 11:40 Back to list

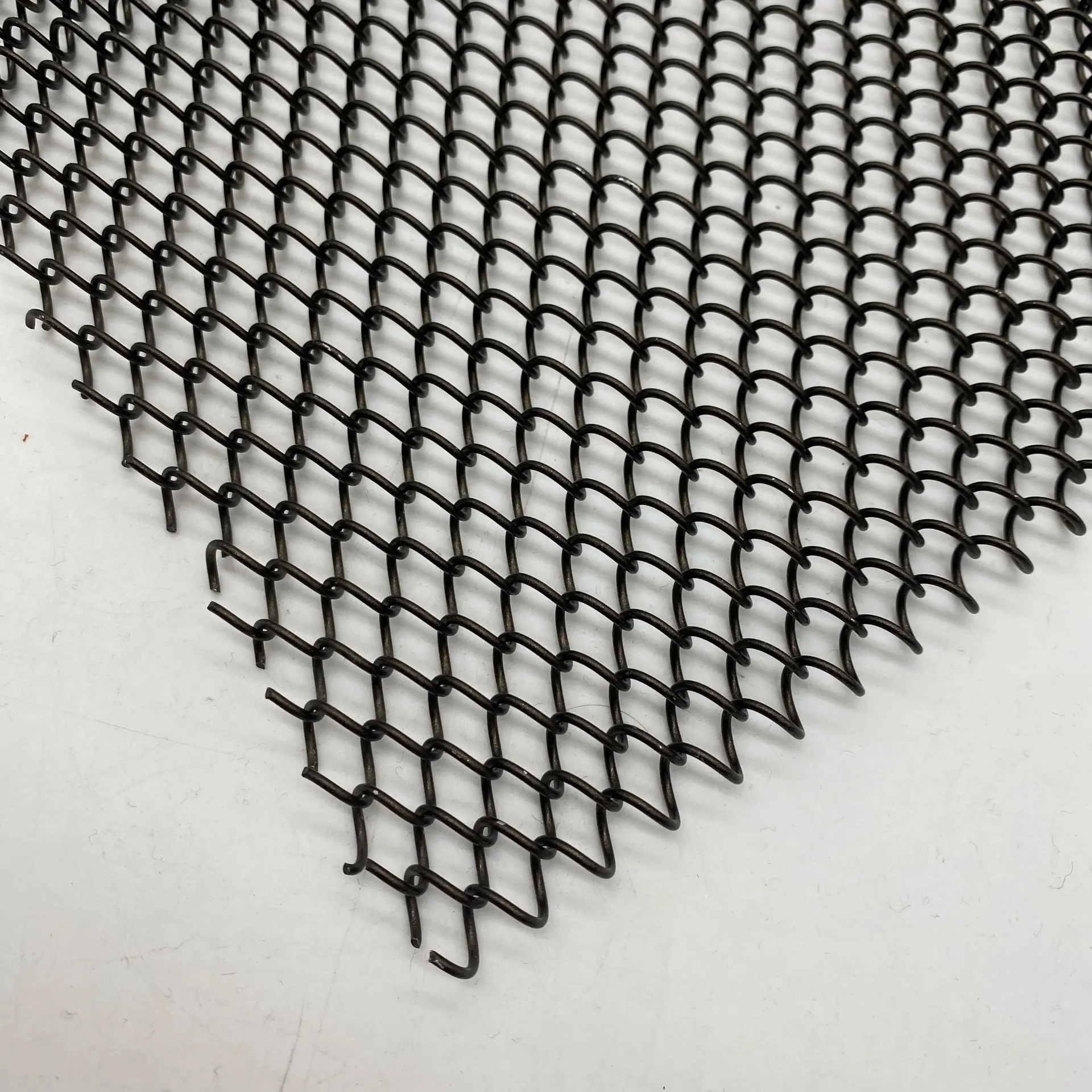

reinforcing mesh

A testament to the authority of reinforcing mesh is seen in industry standards and regulations. National and international building codes often specify the use of reinforcing mesh, given its proven track record in safeguarding constructions. These standards are updated regularly to incorporate the latest research, emphasizing reinforcing mesh’s status as a trusted product. By adhering to these standards, construction companies demonstrate their commitment to safety and quality, further establishing their projects' trustworthiness. In practical application, the installation of reinforcing mesh requires a level of expertise that underscores its specialization in construction. Workers must understand the proper placement and tying techniques to ensure that the mesh performs optimally. Experience in these skills translates into stronger, safer structures that stand the test of time. Specialist training programs for construction professionals emphasize these techniques, reinforcing the industry's commitment to excellence. For environmentally conscious projects, reinforcing mesh presents a sustainable choice. Its durability reduces the need for frequent repairs and reconstructions, conserving materials and energy. Some manufacturers are now producing reinforcing mesh using recycled steel, contributing to greener building practices. This aligns with global movements towards sustainability in construction, rooted in expertise and trustworthiness. Reinforcing mesh’s evolution reflects technological advancements and a deep commitment to safety and efficacy. As construction continues to advance, reinforcing mesh will undoubtedly remain a cornerstone of the industry, exemplifying engineering excellence and reliability. It's not just a product; it is a critical investment in building a safe and sustainable future. With its proven benefits and broad applications, reinforcing mesh solidifies itself as an invaluable asset in the realm of construction.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA