Jan . 17, 2025 02:24 Back to list

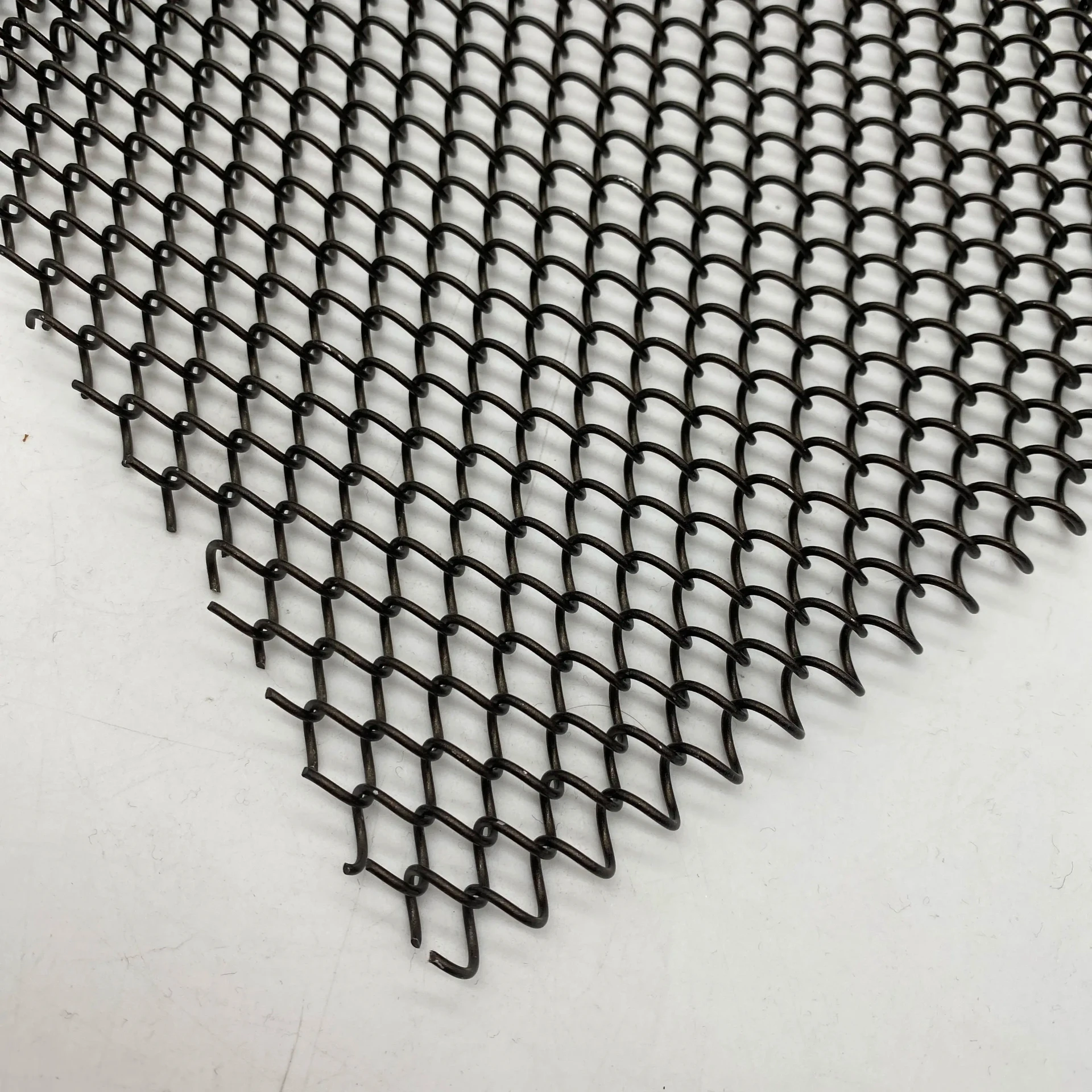

plastic coated wire fencing

In recent years, advancements in design and technology have seen the emergence of smart gully grids equipped with sensors that allow for remote monitoring of water levels and grid blockages. These innovations enhance operational efficiency by enabling timely maintenance and reducing the likelihood of flooding. Authorities can leverage these smart systems to develop more responsive and adaptive urban water management strategies, particularly critical in densely populated urban centers. Trustworthiness in product choice is further underscored by adherence to industry standards and certifications. Reputable manufacturers ensure their products meet or exceed these standards, offering additional peace of mind through comprehensive warranties and after-sales support. When selecting a rectangular gully grid, verifying these credentials is crucial to ensure long-term reliability and performance. Moreover, an authoritative approach to purchasing rectangular gully grids involves sourcing them from established and reputed suppliers who offer a track record of quality and technical support. Conducting thorough research, reading customer reviews, and consulting industry experts can aid decision-making, ensuring that investments in infrastructure yield the desired outcomes in terms of safety and efficiency. In conclusion, rectangular gully grids are more than just functional elements; they are pivotal in ensuring effective urban drainage systems. By combining professional expertise, advanced materials, and technological innovations, these products can significantly contribute to urban resilience against climate variability. As demand for efficient drainage solutions grows, continuous development and improvement in gully grid designs will remain central to shaping cities that are not only safe but also sustainable.

Latest News

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Competitive Galvanized Grating Price for Durable Flooring Solutions

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA