Mar . 07, 2025 01:39 Back to list

rebar mesh for concrete

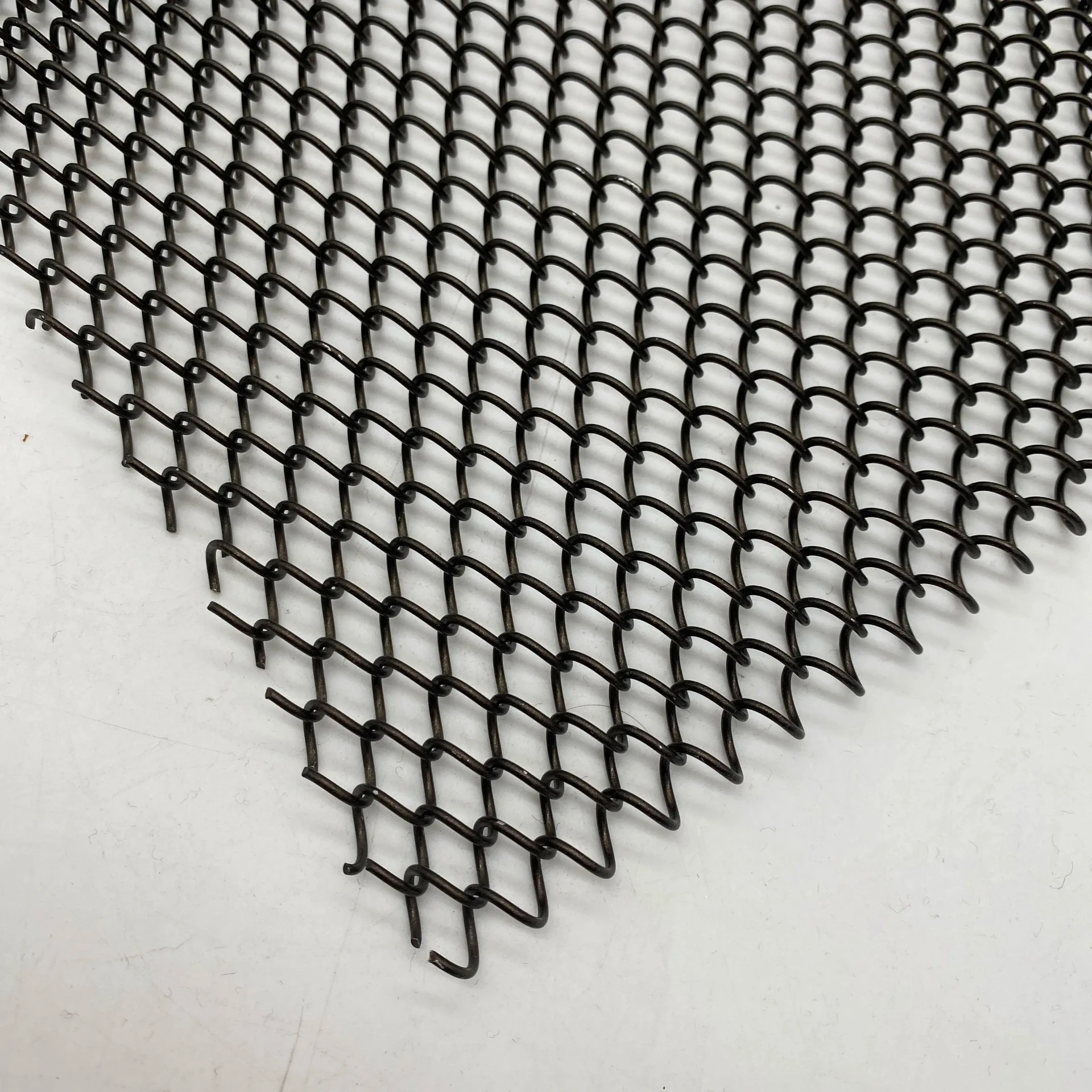

For product-class buyers, understanding the intricacies of rebar mesh specifications can significantly impact the outcomes of their projects. Mesh comes in various thicknesses and spacings, each suited to specific applications. For instance, thin, closely spaced mesh is ideal for residential flooring where lighter loads are expected. In contrast, thicker, more widely spaced mesh suits industrial settings with heavier traffic or loads, such as warehouse floors or parking lots. Quality assurance is paramount when selecting rebar mesh. Ensuring that the supplier adheres to quality control measures in production guarantees that the mesh will perform as intended when faced with real-world demands. Reputable suppliers often provide documentation certifying that their products meet necessary standards and are subjected to rigorous testing, thus reinforcing confidence in their use. From environmental and economic perspectives, using rebar mesh contributes to sustainable building practices. Steel, being the primary material in rebar mesh, is highly recyclable. At the end of a structure’s lifespan, the steel can be recovered and reprocessed, reducing the environmental impact of new material production. This characteristic aligns with modern construction's shift towards more sustainable practices, minimizing waste and conserving resources wherever possible. In conclusion, rebar mesh for concrete embody the essence of Experience, Expertise, Authoritativeness, and Trustworthiness. Its proven ability to enhance concrete performance, coupled with its practicality and sustainability, makes it indispensable for modern construction projects. Understanding the nuances of its application ensures that both contractors and clients can maximize the structural benefits it offers, advancing the industry towards structures that are not only safer and more durable but also constructed with a keen eye on efficiency and sustainability.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA