Mar . 06, 2025 12:18 Back to list

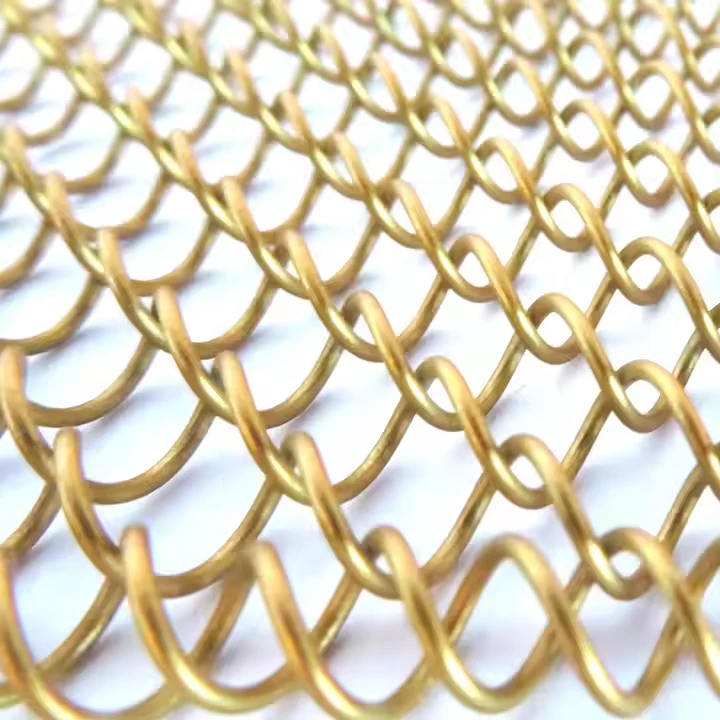

rebar mesh

Trustworthiness in the use of rebar mesh also hinges on proper installation and inspection. Employing qualified personnel for installation, who are adept at interpreting engineering plans and executing them with precision, is fundamental. Inspection processes should verify that the mesh is positioned according to design specifications and that any issues of misalignment or kinking are promptly rectified. Inspections should be ongoing throughout the construction process to maintain structural integrity and uncover potential oversights. Ultimately, the efficiency and dependability of rebar mesh make it a preferred choice in contemporary construction. By embedding this material within structures, engineers and builders not only boost the longevity of their projects but also enhance safety and sustainability. Its role is pivotal in the creation of modern marvels, underpinning everything from skyscrapers that define city skylines to the foundational infrastructure that keeps society connected. Investments in the latest technologies for rebar mesh production further advance its application. Automated welding systems and high-precision measuring devices enhance the quality and reduction of material waste. Forward-looking construction companies are increasingly embracing these innovations, recognizing that high-caliber rebar mesh products complement their commitments to excellence and efficiency. This comprehensive insight into rebar mesh underscores its indispensable nature in the construction industry. With the continuous evolution of construction methodologies and the ever-growing demands for resilient infrastructure, rebar mesh remains integral, contributing to the building of a safer, more reliable future.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA